There will be no chemical or anchor bolts in this material.

Now the market is full, full of various dowels, not only by the type of fastening, but also by weight load. I will try to describe in detail where and which dowels are used, both for heavy structures and light ones.

At the first stage, we will tell you about dowels for plasterboard sheets.

The difficulty of attaching to drywall is not only in its low strength, but also in the presence of voids between the cladding and the wall. Because of it, the contact area of the hardware with sheet material is very small and does not allow to hold any heavy load.

Therefore, the nail dowel for drywall must have a special device that will provide either a spacer inside the sheet or crimping it on both sides. Depending on the design, such dowels can withstand different loads, and therefore each of them is designed for specific purposes.

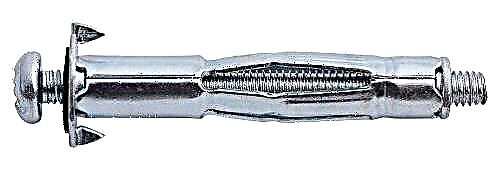

Dowel DRIVA.

They are divided into metal and plastic dowels.

Plastic is most often made of nylon, metal of zinc. The price for a plastic dowel is about 2 rubles, for metal 20 rubles.

Application: for attaching lightweight constructions to drywall. The dowel has a large thread guaranteeing a secure fit and preventing it from spinning during installation. No need to drill anything, you can immediately wind up in hl. To facilitate screwing, it is possible, but not necessary, to drill a 6 mm hole.

The desired load is up to 6 kg for plastic and up to 10 kg for metal. I do not recommend a higher load for this dowel. For better fastening it is recommended to use a fastener with a diameter of 3.5-4.5 mm. The only possible complication during the installation process may be the selection of a screw of a certain length. P

Required screw length = dowel length + thickness of the attached structural element + 1 screw diameter.

- The diameter of the rod is from 12 to 15 mm,

- The length of plastic products is 23-33 mm,

- The length of metal products is 33-44 mm,

Note. This drywall dowel may be the only possible type of fastener if the gap between the wall and the cladding is very small.

- Very convenient and easy to use.

- No additional tool needed.

- Affordable dowel cost.

- When mounting is not required, special training or qualifications.

- disadvantages include load limits.

- Sometimes a nylon plug will crack and break, so take a stock before you buy.

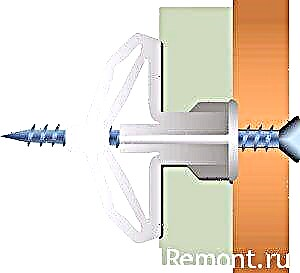

Dowel butterfly.

The most popular dowel for drywall.

The main manufacturing material is polypropylene.

Price 10 rubles for a dowel with a self-tapping screw.

Application: for fastening lightweight structures to sheet materials (drywall, plywood, chipboard).

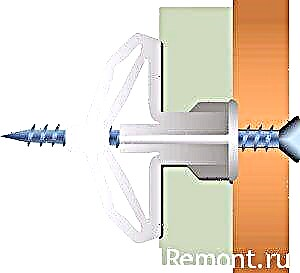

Drill a hole along the diameter of the dowel (drilling is carried out only in rotation mode, with the impact turned off). Then it is necessary to insert the expansion bolt shield, having previously squeezed its folding parts, so that behind the sheet of drywall or plywood the folding parts are located vertically. The required material or element is attached to the installed dowel with a screw.

- Dowel diameter 8 - 10 mm

- The length of the plastic dowel is 28 - 50 mm

- For an 8-28 mm dowel, a 3.5 / 35mm self-tapping screw is suitable.

- 10-50 mm suitable screw 3.5 / 55mm.

- Butterfly size 10/50 mm can withstand up to 15kg.

Pros .

- Quick installation

- Any hardware store is always in stock.

- There is no doubt that the dowel will be securely fastened to the FCL.

- Providing Extra Stiffness . If you screw in the butterfly anchor, its legs spread apart. Due to this, additional rigidity of the entire structure is achieved, which is especially important when working with GCR from two layers

Varieties

There are many types of fasteners used to install drywall products. But it’s important to choose more appropriate products for a particular option. In addition, you should know the installation rules of the described mounting parts, which will ensure the reliability and durability of the formed structure.

The dowel used to fasten GKL products must comply with a number of requirements:

- have a corrosion-resistant coating

- be made of high quality and durable metal,

- spacer elements of the part must ensure a benign fixation of the drywall base to the base surface of the structure.

All dowels for drywall differ in that they are made according to the harpoon spacer principle, which provides a strong and reliable fastening.

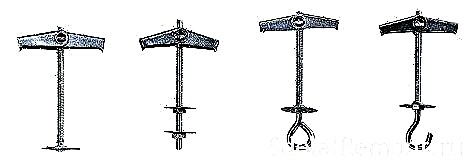

There are two main groups of drywall dowels:

- walk-through

- unclenching.

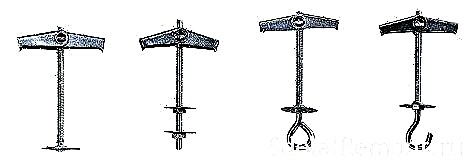

Passers are extremely comfortable for ceiling mounting.

More often used to install powerful chandeliers, interior spotlights and sports equipment. The spring-loaded dowel consists of an iron threaded rod, folding lock wings and a spring mechanism. In the void on the inside of the drywall structure, the spring mechanism opens the wing-locking hooks, thereby creating a reliable mount.

The end of the spring dowel for drywall can be made in the form of a ring, half ring, screw or rod. The desired type of tip is selected, focusing on the type of object that you want to attach (for example, a ring-shaped tip is traditionally used for attaching electrical wires, and in the form of a hook half-ring for hanging various lighting equipment).

The spring dowel is perfectly suited for mounting parts to plasterboard walls, tiled. In order to decide what type of clamps of the type described is suitable for your design, it is worthwhile to take a closer look at the pros and personality of the introduction of each type of dowels.

Dowel molly

The dowel molly just can not be attributed to cheap fasteners, the cost for it is really high, but there is no reason to doubt the quality.

The principle of operation of the dowel molly:

- A hole with an eight-millimeter diameter is made under this dowel with a drill,

- After this, the molly is inserted into the gypsum plasterboard, the two-pronged side is pressed close to the sheet, which helps prevent the anchor from scrolling at the fixing step,

- Then the screw supplied with the molly dowel is screwed onto the sheet with a screwdriver.

It should be noted that the central part of the sleeve is twisted, which gives a reliable fixation of the molly in drywall.

The rivet will be in place.

Advantages of molly:

- The ability to withstand fairly high loads,

- There is a function of dismantling if necessary,

Molly screws are included with dowels.

Driva

Driva is one of the most popular types of fasteners. The driva is produced in 2 types - plastic and metal.

A plastic driva dowel is purchased more often, and there are more on sale.

How to fix the doweldriva:

- Drill a hole in 6 mm,

- Insert the dowel,

- Use a cross nozzle to cut it into the GCR like a regular self-tapping screw,

- After that, screw a screw or a self-tapping screw with a diameter of 3.5 or 4.5 mm into the internal cross-shaped slot of the driva dowel.

The difficulty can only appear in the selection of a suitable self-tapping screw. When choosing a self-tapping screw, consider that driva has a length of 23 mm (plastic) and 33-44 mm (metal).

In terms of cost, such dowels under any drywall look extremely attractive, and what else distinguishes a dowel - it does not need a free zalisty space.

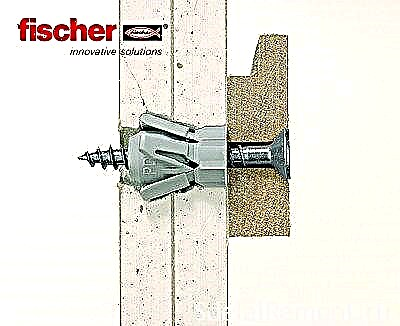

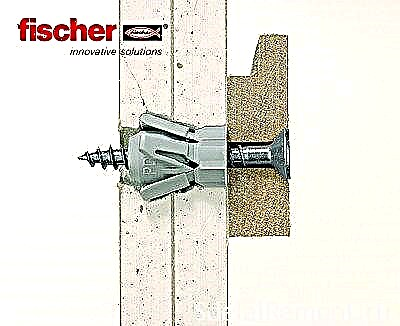

It remains to mention another well-known brand of fasteners - fischer.

Fischer pd

Otherwise, fischer pd is called a butterfly plug. This is a little false, since other manufacturers also produce butterfly dowels for drywall, but specifically fischer pd is more associated with this type of dowel for drywall sheets.

The fischer pd consists of a plastic base, i.e. a butterfly, into which a screw is screwed.

During installation, the butterfly is pressed against the joint and snugly adheres to the screw. Thus, the element has protection against falling out.

Fischer pd is not difficult to mount, at a cost it is quite attractive. Fischer is one of the most popular fastener brands.

Dowel nail

The most popular and widely recognized expansion dowel-nail is used to fasten the product to a concrete base. The spacer part of this dowel is nylon and consists of 3 sections. In the rear part there is a passage hole, which simplifies screwing and provides sufficient axial movement of the screw. The dowel is held securely due to the bursting of its walls immediately in 3 directions.

The product is used for through installation:

- cornices

- window frames

- door frames

- racks

- skirting boards and other products.

Steel dowels for sighting are used when installing heavy structures, carried out by a special dowel mounting gun.

This type of the described type of fasteners along with the dowel screw, dowel-mungo, dowel-bolt, anchor-dowel and other fasteners is used quite rarely for installation of gypsum plasterboard.

Specialists prove this by the fact that the spacer element does not provide a sufficient level of fixation of the base of the wall to the gypsum board.

Self tapping screw

The expansion bolt shield screw used for installation of gypsum plasterboard is:

- nylon (TT22 brands),

- metal (DRIVA).

Such dowels are used to fasten the necessary objects on multilayer or single-layer drywall sheets having an insulating or decorative coating on the inside.

They vary in size. Choosing the appropriate parameter, pay attention to the fact that the fastener is not very long - it should not stick out on the other side of the GK-layer of the skin.

Such parts are especially suitable for working with strong gypsum fiber m. Self-tapping screws are also irreplaceable and for screwing some heavy object to the drywall wall. In order to do this, you just need to tighten the self-tapping screw in a marked place in advance using a screwdriver or a screwdriver.

Traditionally, the fastener without problems is screwed into the gypsum wall board of any thickness.

If the sheet thickness is more than 15 mm, a hole must be drilled before screwing in the screw.

"Butterfly"

The dowel, called the "butterfly", has an all-purpose purpose. This is a part that, when screwing on the reverse side of the sheet, forms a typical drop-down stop that can withstand a solid load providing the greatest distance. So that the dowel does not turn, it is provided with a special cuff. Prior to this, before installing the butterfly dowel, it will be necessary to pre-drill the landing hole.

When planning to use a butterfly dowel, note that the thickness of the fixed product does not have to exceed 5 mm.

"Umbrella"

As can be seen from the name of this dowel, it works on the principle of a real umbrella, that is, it opens in space behind the stove, thereby providing a reliable stop.

An expansion bolt shield umbrella also demands preparatory drilling of an opening before installation. It is unsurpassed for the GK-ceiling. For example, when installing a heavy chandelier, the stops opened in the space behind the sheet will moderate the load distribution over a significant area.

To work with dowels of this type it was more convenient to use auxiliary tools, for example, special tongs.

Drywall plug with drill

You can also find a dowel under any gypsum board with a drill at the end. This is a self-tapping screw that is designed to screw into

It is better to fix this type of drywall dowels on single-layer and multi-layer plates, in case there is an insulating or decorative coating on the inside of the partition.

In length, such dowels under drywall should not go beyond the other side of the partition.

For double drywall

The above dowel is just right for double drywall. Double drywall is used in structures of special strength or structures that must be perfectly soundproofed.

Dowels for such drywall must be strong, reliable, aggressively fixed in.

Screw

Nail dowels, as they are commonly called, consist of a dowel and specifically a screw-cut nail.

They are often used for ceiling hollow structures.

Drywall nails for drywall should be perfectly screwed, but not scrolled, so compare the size and complexity of the work.

Metal

Metal dowels are traditionally made from zinc alloy. In terms of cost, it is actually constantly more expensive than its own plastic counterpart, but this is fully explainable - iron screwdrivers are stronger, less deformed during fixation, and last longer.

In massive structures, it is more reasonable to use specifically iron fasteners, and small or lightweight structures can be completely assembled using plastic parts.

How to fix a spring dowel

A dowel with its wings folded together penetrates into the drilled hole.

An integrated spring must spread the dowel wings as soon as they reach the void.

The wings are unsurpassed in fixing the structure, and the screw can be fastened with a screwdriver or a screwdriver. Such a dowel is often used to hang a chandelier.

Chemical anchors

Such drywall anchors are not afraid of overload when fixing in

A chemical anchor is a capsule or cartridge with an adhesive texture. When you begin to attach the anchor, the capsule is crushed and its composition is mixed.

A chemical reaction occurs and a monolithic fastener appears. In addition to this anchor, there is a mesh sleeve, which makes the attachment heavy-duty.

Installation Features

Even a novice master can tighten the dowel in the GCR. To do this, it is enough to know a number of simple rules:

- The hole in the drywall, drilled under the dowel umbrella and at least some other type of dowel fasteners, must be larger than the diameter of the part itself, otherwise the sheet may be damaged during installation.

- If you use an electric screwdriver when installing the dowel, then try to prevent the fasteners from turning in their place at the end point - this can adversely affect its density.

To do this, it is not necessary to tighten the part completely. The final turns are best done manually or with a cordless screwdriver with the desired setting.

In order for the dowel-butterfly to be firmly fixed, you must first drill a hole of the desired diameter, then firmly press the folding wings of the part with your hand and carefully insert it into the hole. To a suitable position, the spring dowel can be twisted using an ordinary screwdriver or a screwdriver.

Fasteners are now presented in a wide range, the price abundance is also enticing.

The choice of dowels depends on the complexity of the design, its functionality and ease of installation.

Why do we need special fasteners for GKL?

Plasterboard sheets - a popular building. They are used for the construction of walls, partitions, leveling of brick surfaces, the installation of ceilings and installation of various structures.

After the repair is completed, there is a need to fix something on the wall. You can decorate a room with a decor element weighing up to 3 kg by screwing in an ordinary self-tapping screw for drywall.For the most languid items, you must use special fasteners.

Plastic dowels with screwed-in screws that are used for brick and concrete will not be kept in GKL sheets.

There are special fasteners that differ in purpose and features of implementation. In order to ensure the strength and durability of the assembled structure, it is necessary to make the right choice of fasteners and know the technology of its installation.

The dowel for drywall must meet the following requirements:

- production of high-quality strong metal,

- the presence of anti-corrosion coating,

- compliance with the standards GOST 28457–90,

- equipping with spacer elements, which serve for reliable fixation in the GCR.

At the base of all dowels is the harpoon spacer principle.

Fasteners are divided into two huge groups:

- 1.

Walkthroughs.

Most often, walk-throughs are used for fixing parts of the interior to the ceiling: chandeliers, spotlights, sports equipment. The dowel is made in the form of an iron rod with a thread, which is equipped with folding plates and a spring mechanism. In the empty space behind the GCR, the locking wings are unclenched, creating a solid fastening.

Spring dowels are distinguished by the type of tip. It can be made in the form of a screw, ring, half ring or rod.

Selected depending on the item to be mounted. A hardware with an end in the form of a ring is used for mounting wiring, half rings for lighting devices.

Varieties of drywall dowels

In order to correctly apply fasteners that will withstand the load and firmly fix the attached objects, it is necessary to understand each type of dowels for gypsum fiberboard: their device and installation rules.

Its second name is the fast-wall plug (DBM).

It is used when there is no free space between the wall and the drywall structure, the sheets are fastened with glue. The spacer consists of three sections, made of nylon, does not have a screw part, is not dismantled.

The hardware is inserted into a pre-drilled hole. Then the nail is hammered with a hammer until it stops. Reliability of fastening is provided by a spacer in three directions. There are two types of this fixture: with a secret hat and in the form of a fungus.

They differ in the height of the side. Fungal dowels hold the parts tighter. The countersunk does not provide the necessary stiffness.

The principle of action of a hardware is similar to an umbrella. Withstands the largest weight in the middle of the fastening parts for GCR. Outside, he recalls an expansion anchor bolt, which is used as a mount on concrete and brick walls. When opened, it provides uniform distribution of overload over a large area, this makes it possible to hang languid structures. It is used when hanging chandeliers to the ceiling. Included are additional hooks and rings.

A hole with a diameter of 8 mm is drilled under the dowel. The hardware is inserted into the sheet of drywall, the two-pronged side fits snugly on the plate, which prevents the anchor from spinning during installation.

Then, the screw from the kit is inserted into the holes. Screwing it on the internal thread, tighten the HA sheet. Only the central part is compressed, the rivet remains in place, which ensures reliable fastening.

The main advantages of hardware molly: the ability to withstand the highest loads and the ability to dismantle if necessary.

From the name it is clear that the mount is based on the principle of an umbrella. Structurally, it consists of two plates that are unclenched by a spring. Opening from the back of the plate, they provide a reliable stop.

The screwdriver installation is usual.

Pre-drill a hole. Insert an umbrella with pressed plates into it. To make it comfortable to work, they use auxiliary tools - special tongs. When screwing in, upon reaching a free place, the umbrella, under the action of the springs, opens and is firmly fixed in drywall.

It is applied to GK-ceilings. If a heavy lighting device is suspended, the spacers disclosed behind the GKL cloth contribute to an even distribution of weight over a significant area.

The umbrella cannot be dismantled.

This type of fastening connection got its name due to the fact that when screwing it forms on the back side an opening stop. It provides a very probable spreader, able to withstand huge overloads. There is a special cuff on the part that protects against scrolling. production - propylene.

First, for the dowel, you need to drill a hole in the corresponding diameter. Then bring the end to it.

Clamp the elastic side elements with one hand, drive the other with a hammer into the housing until it stops. Then attach an object for fixation to the base. Insert a screw into the threaded sleeve and, by screwing, deform the side wings until they fit snugly against the back of the plate.

The butterfly is used for products whose thickness does not exceed 10–15 mm. It is used for hanging lamps, laying electrical wires, for attaching baseboards, sockets, switches, cornices. Plus butterfly dowels in the easy screwing of screws, the ability to dismantle.

The disadvantage is that it cannot be used with limited back space.

Popular due to ease of installation and low cost. Outside it looks like a conical rod with a flat head, equipped with a screw cut of an acute-angled profile. On the hat there is a cruciform recess, designed to screw the hardware and self-tapping screw. Inside there is a through or blind hole for screwing in the fixing screw.

Drives differ in design: with a drill in the form of a perk or trident and without it.

manufacture: alloy - zinc alloy or plastic - propylene. The second option is in great demand and cheaper.

The installation process is easy. First, drill a hole with a diameter of 6 mm. Then fasteners are inserted into it and cut into drywall with a screwdriver just like a screw.

Further, a self-tapping screw is screwed into the internal cruciform gap with a diameter of 3.5 or 4.5 mm. It’s basically right to choose the size.

The design of the Drives allows you to fully gain a foothold in the GCR. According to manufacturers, it can withstand a load of 25 kg. Plus driva dowels in small sizes, iron ones have a length of 33–44 mm, plastic ones - 23. The second advantage - does not ask for a free place behind the HC sheet. Possible dismantling of the mount.

It often happens that you need to hang a shelf or even a cupboard.

But what if the repair was made not so long ago, or the house is fresh, and all the walls are made of drywall? You just can’t drive a nail into it and you can’t screw it in - it will just fall out.

Drywall - sheet A wall from it is a hollow structure. And for all hollow structures it is required to have fixing dowels in order to attach something to the wall. Let's look at some popular types of fasteners for drywall.

Butterfly dowel (cheap)

Our hit parade is opened by the popular "butterfly" in the ranks.

For its installation, make a hole with a diameter of 10 mm, insert a dowel into it and screw a medium-length self-tapping screw. When screwed in, the dowel makes a spacer that holds it in the wall. Screw in the screw carefully, with excessive force, the dowel can be damaged. For this type of fastener, it is better to use self-tapping screws with a diameter of 4.2 mm, they better burst the body of the dowel from the inside and, accordingly, are better held in the hole.

Typical dimensions of the dowel for drywall: 4x32, 4x46, 4x55 mm.

Driva expansion bolt shield

This type of fastener has only one advantage - the speed of installation.

It is enough to put it on a screwdriver bit and screw it into the wall. Then, without changing the equipment, a self-tapping screw is twisted. Reliability of fastening slightly surpasses reliability of a plastic butterfly. There are iron and plastic dowels. For the plastic version, it is necessary to pre-drill a hole, and later screw the dowel with a screwdriver to prevent the plastic cross-shaped slot from breaking.

However, there is a trick thanks to which you can twist it with a warped slot.

To do this, it is necessary to grind a thin slot on a twisting surface with a narrow angle grinder or a construction knife and tighten with a flat screwdriver.

Typical dimensions of a wall plug for drywall for drywall: 14x32, 14x38 mm.

Aluminum Anchor Molli

Molli opens behind a sheet of drywall like an umbrella. Sales consultants often recommend that to install this fastener it is enough to drill a hole and tighten the screw. But with the technique given to us, the fasteners will not open, but it will damage the GCR.

For the proper installation of this dowel, a special tool is needed - a rivet.

However, if you already have such anchors, and you need to suspend the shelf, you can fix the problem by taking a wire cutter and a screwdriver. To do this, insert the fasteners and tighten the screw slightly. Then it is captured by nippers and slightly pulled out, and again a screw is slightly twisted. Repeat the operation until the fastener is firmly fixed.

Strength of fastening is considered one of the best.

When you try to pull out the anchor, pieces of drywall are opened along with it.

Typical dimensions of the Molly dowel: 4x21, 4x32, 4x38, 4x46, 4x54 mm.

Butterfly HILTI, Knauf and other dear

One of the most expensive dowels. The development of the installation is no different from the installation of a cheap butterfly. The butterflies given to us have paws that abut drywall, differ in larger area, which means that they provide tremendous reliability of fastening.

But if you do not hold out the self-tapping screw, then the strength will be comparable to the Driva dowel.

Typical sizes are the same as those of a cheap butterfly.

As you can see, cheap dowels behave unpredictably during installation, and extremely light objects can be hung on them. Therefore, do not save on fasteners. It’s better to get something better and not wait until the shelf with books falls on your head.

What fasteners are used in drywall constructions

Plasterboard constructions include several in - hl (gypsum plasterboard), iron profile, wood struts (if necessary reinforcements).

In addition, the design itself must be attached to the supporting wall. It can be wood or concrete (brick). The abundance of used ones entails the need to use different hardware.

GKL fasteners

Before installation, you need to find which screws to fix the drywall to the profile.

It depends on the frame to which the sheets will be attached.

Self-tapping screws for drywall on the alloy are a screw with a rod in the form of a cone, pointed at the end. They are used to fasten hl to the iron profile. If the alloy thickness exceeds 0.7 mm, then screws are suitable for the profile with a drill at the end, instead of the usual sharpening. They are used for profiles with a wall width of 07-2.2 mm.

1 - for metal, 2 - for wood

Wood self-tapping screws are an analogue of alloy self-tapping screws. Their difference is the pitch of the thread.

A wood screw has a larger thread pitch, compared to alloy screws, and is used for attaching hl to a wood structure.

Prosekatel - candidacy for screws

The elements of the iron frame under the hl design are traditionally fastened with the help of self-tapping screws "bugs".

This method is robust, but it takes a relatively long time to screw in a screw. This problem was resolved with the occurrence of a notch.

The notch is a mechanism that works on the principle of ordinary scissors, but instead of blades it has a spike piercing the alloy. To fasten two elements of the frame, you need to lay them on top of each other, install the screener in the desired place and press on the levers. Bonding occurs due to the fact that the alloy bends into the hole and wedges.

When using the cutter, it is not necessary to think with which screws to fix the profile for drywall, because they are completely absent there.

Benefits of the notch:

- fastening speed

- does not ask for electricity,

- lack of protrusions in places of fastening.

Its disadvantages:

- the strength of the joint is inferior to the self-tapping screws, but sufficient to erect hl of the structure

- there are a lot of low-quality fakes on the market that quickly fail.

Features, classification and installation of dowels for drywall

The dowel for drywall is needed in those cases when there is a need for fixing this to any structure or wall.

For fixing lightweight constructions, photo frames, for example, this element may not be useful, in other versions it can be used to create a strong and reliable mount.

In the repair field, as well as in everyday life, completely different situations appear that have certain requirements and personalities. And in order to ensure the best result, you need to choose the right dowels based on their classification. In this article, we will talk about how to choose how to screw a dowel into drywall.

Dowel Molly.

The Molly dowel performs the function of attaching structures to hollow bricks, blocks, sheet materials. For example, to drywall, fiber cement, floor slabs.

One of the expensive options for dowels, which belongs to the category of "expandable". Suitable not only for drywall, but also for suspended ceilings. During installation, the dowel clamps the drywall between the front and rear.

This dowel can withstand up to 35 kg. The price of a dowel depends on the diameter from 40 to 120 rubles apiece.

Like the “butterfly”, the Molly dowel for drywall, when the screw is tightened, forms several stops on the reverse side of the folding parts of the sleeve. But outwardly they look more like not the wings, but the spokes of an umbrella.

What is a dowel

If necessary, fix a heavy picture on a plasterboard wall, attach a TV to the partition, hang a chandelier, special fasteners will be needed, with which the surface will not be deformed, and the object is in its place, while performing its functions. These fasteners are dowels.

Another purpose of dowels is to fix the elements of the drywall structure during installation. Fastening the components of the frame under the drywall is carried out quickly and efficiently.

The dowel for hyproc has various shapes in appearance. Depending on the purpose, it is made of materials capable of realizing functions without defect.

Each dowel is designed for weight distribution

Each dowel is designed for weight distribution

How to distinguish the dowel for its intended purpose? How is the fastener fixed?

Types of drywall dowels

This fixture is used in many repair and construction works. For drywall, there are some types that will create fixing strength, while the surface will remain pristine.

Butterfly dowel

This type of dowel can be called a simplified version of the molly, the installation of which also foresees a hole prepared in advance.

After organizing it, it will be necessary to put the dowel into the drywall and fix it, and only then, using a screw, press the back of the sleeve to the inside.

To do this, you will need to turn the screw clockwise. Spacing wings need to be spread.

The butterfly has the same advantages as the moth.

The only difference is the smallest overload (up to 28 kg).

About driva dowels, plastic and iron for drywall, let's talk below.

The expansion bolt shield the butterfly with the self-tapping screw for gypsum cardboard (photo)

Nail

This variety is used to create a stationary mount, which does not imply the next dismantling of the structure.

It can be used in the installation of door gaps, cornices, skirting boards and more.

The dowel is also inserted into the hole prepared in advance, and then hammered with a nail with a hammer. The main advantage is the speed of installation.

In addition to the varieties of this device, there are differences in the way they are made of. So there are dowels made of alloy, plastic and nylon. The first option is considered more robust, reliable and expensive, while others are the most affordable, but at the same time, the least strong and reliable.

Read about the sizes and other characteristics of dowels for drywall (butterfly, molly, etc.) below.

Drywall with wall plugs

Specifications

When choosing a dowel for drywall, you need to take into account not only their variety, but also the technical properties.

So on the modern market there are models with diameters (mm):

- 3,0,

- 4,0,

- 4,5,

- 5,0,

- 6,0,

- 8,0,

- 10,0.

The length of the dowel under the drywall can be (mm):

- 12,0,

- 16,0,

- 25,0,

- 30,0,

- 35,0,

- Up to 260.0.

Now we learn how to screw the dowel into drywall.

Dowel for drywall: classification

Manufacturers of gypsum plasterboard sheets (gypsum plasterboard) provide for the possibility of attaching gypsum plaster to both the iron or wood profile, and among themselves.

It is also allowed to fix any lightweight structures onto the plasterboard itself, such as small shelves, lighting chandeliers, photo frames, etc.

For fasteners of the components of the frame, as well as additional parts to the surface of the drywall, such components for drywall as fasteners, for example: crab, anchor, dowels, etc. are responsible.

Next, we consider the more common types of fasteners, their internal classification.

A simple dowel-nail is held due to the friction force between the walls (concrete, brick) and the part of the fastening hidden in them. Drywall has a thickness of not more than 24 mm. It is mounted to an iron or wood frame and there is a void or a layer of insulation behind it, therefore there is no friction force suitable for fixing the nail. If necessary, hang on the GKL or GKLV paintings, shelves, small cabinets using special alloy or plastic products with special mechanisms.

GCR cost

The price of drywall fasteners depends on the type, manufacturer, size, batch size.

| Name | Sizes, mm | Price, rub / pc |

| Folding spring with a Tech-Krep SPDK M4 hook | 4 x 75 | 28 |

| M5 | 5 x 95 | 34 |

| M6 | 6 x 100 | 45 |

| M8 | 8 x 100 | 65 |

| Butterfly TNF | 10 x 50 | 1,2 |

| With Tech-Krep Molly Bolt | 4 x 32 | 11 |

| 5 x 52 | 22 | |

| 6 x 52 | 18,5 | |

| With Tech-Krep Molly Hook | 4 x 32 | 14 |

| 5 x 52 | 16 | |

| 6 x 52 | 16 | |

| metal Hort Driva | 15 x 29 | 10 |

| Plastic Hort Driva | 12 x 32 | 1,5 |

| LEGS | 17 | |

| PD Fischer for plates (nylon) | 8 x 29 | 7 |

| 10 x 28 | 9 | |

| 12 x 27 | 11 | |

| PD S Fischer for woodworking boards | 8 x 29/4 x 40 | 14,5 |

| 10 x 28/5 x 40 | 19 | |

| 12 x 27/6 x 50 | 23 | |

| GK GREEN Fischer Environmentally Clean Nylon | 7 | |

| with screw | 12 | |

| Knauf Hartmut | 5 x 60 | 93 |

For fixing various objects to drywall, ordinary dowels and nails are unsuitable; special fasteners designed for this type are required.

Their design was created taking into account the features of GCR. When choosing, take into account the expected load, the location of the hole, other reasons. You can hang the chandelier on the option with a hook or a ring. In the nursery, it is recommended to use dowels made of ecologically clean nylon. If the speed of the work is crucial, it is better to choose Driva that does not require drilling. Weighing objects (more than 35 kg) can withstand only Knauf Hartmut.

The expansion bolt shield a nail for fastening of profiles

The most popular nail dowel for attaching profiles and suspensions to a concrete wall consists of 2 parts. The first part: the tip - contains 2 sections, it is made of plastic. The second part is the nail on which the thread can be applied. For mounting the frame under drywall, dowel nails in sizes 6/40, 6/60 are used. To fix the guide profile to the wall, these fasteners are applicable. However, for fixing the suspensions, it is required to use a metal anchor, since a large load is placed on the suspension, which the nylon dowel is not able to withstand due to its technical characteristics.

Dowel-nail for attaching the guide profile to the concrete wall

Dowel-nail for attaching the guide profile to the concrete wall

Dowel action

On the plastic part are the antennae. They straighten out when a nail enters the tip. The antennae are fixed in a concrete (brick) wall, while firmly holding the mass of the object being hung. The main basis for the use of fasteners is the fixing of profiles to the rough base during installation of the frame under drywall.

Knauf nail dowel with various cuff shape

Knauf nail dowel with various cuff shape

These dowel nails for drywall have 2 types - the usual and restrictive cuff, which does not allow the metal nail to “fall through” inside.

| Name | Number of pieces in a pack, pcs. |

| Impact screw 6*40 mushroom hat | 100, 200 |

| Impact screw 6*60 mushroom hat | 100 |

| Impact screw 6*60 sweaty hat | 100 |

| Impact screw 6*80 countersunk hat | 100 |

| Impact screw 8*60 countersunk hat | 100 |

| Impact screw 8*80 countersunk hat | 50 |

| Impact screw 8*100 countersunk hat | 50 |

| Impact screw 8*120 countersunk hat | 50 |

Options fasteners in GVL

Next, we consider the most popular options and what can be twisted into a drywall sheet, for reliable fastening of various decorative elements.

Easiest option - this is to find the guide profile using a magnet and screw it into a steel screw with a screwdriver. If this cannot be done then it is necessary to resort to the help of special fasteners in the drywall sheet.

The most common in works related to drywall is the dowel "butterfly". In appearance, it has a butterfly with spread wings. The main material for the manufacture of fasteners is polypropylene. Also on sale are metal products.

Photo of the most common dowel for drywall “Butterfly”

Photo of the most common dowel for drywall “Butterfly”

Butterfly action for drywall

Initially, a hole of the right size is made with a drill. There you need to insert the plastic part of the dowel. To do this, the side elements are pressed to the center, the dowel is driven in with a hammer. This should be done carefully. Then a screw is screwed into this part. At the time of mounting the self-tapping screw, the polypropylene part opens on the reverse side of the drywall surface (as if the wings are spreading to the sides). They abut against GCR, thereby rigidly fixing and distributing the suspended weight over the surface, there is no point load.

The butterfly dowel has a distinctive property - it is possible to dismantle the fasteners from the plasterboard surface.

Butterfly has various sizes. Their selection depends on the weight of the item:

- Size 8/28. We use this dowel for fixing a lightweight construction. Self-tapping screws for the "butterfly" should be purchased separately. For this size, the screw 3.5 / 35mm is most suitable. Screw coating is absolutely unimportant. The dowel hole is made with an 8 mm drill. The inserted fixture has a latch that prevents the butterfly from completely “falling through” inside.

- Size 10/50. Inside the wings of this dowel there are 2 slats that give extra strength when fixing to the base from the back. This butterfly is capable of supporting a weight of 24 kg. For a butterfly size of 10 * 50, you should purchase 3.5 / 55mm screws. The hole for this butterfly will require a diameter of 10mm.

Mounting butterfly dowels

Mounting butterfly dowelsMolly Screw Mounts (MOLLY)

The MOLLY dowel for drywall is used if it is necessary to fix a heavy object on the surface. It is perhaps the most reliable mount.

In its structure, Molly differs from plastic dowels in a completely metal frame. The material is galvanized or stainless steel. The dowel consists of a sleeve and a screw. The second part is sometimes selected independently, depending on the assigned functions - it can have an ending in the form of a head, ring, hook.

Molly dowel has teeth for solid surface fixation

Molly dowel has teeth for solid surface fixationThe sleeve has slots through the entire element, this creates a spacer part. In the center of the sleeve there is a thread for a screw. When buying a separate screw, you should pay attention to this.

The screw included in the kit has a support washer, which is a kind of limiter - without it, the fasteners scroll in the spacer.

Mount Molly

For the installation of the dowel molly, a special expansion device will be required.

- It is required to make a hole in the plane with a size selected for the size of the dowel from 8 to 13 mm.

- Next, a sleeve (collet) is inserted into the hole. It is driven in until the denticles on it hit the surface.

- After that, a screw is screwed.

- Use special pliers to pull the screw out. With this action, the end of the collet is attracted to the surface from the back side, the spacer part is activated and fixed.

Molly Mounting Scheme

Molly Mounting SchemeDepending on the size of the Molly, there are different weight categories. Basically, the quote goes from 25 to 75 kg. up to 30 kg can be hung on a plasterboard surface using this dowel. weight.

The dowel is presented in more detail in the photo

It is possible to purchase a sleeve with a hook in the Molly dowel

It is possible to purchase a sleeve with a hook in the Molly dowelKNAUF Hartmut Mounts

This dowel has 4 components:

- the anchor plate is a galvanized U-shaped plate,

- There are 2 guide antennae made of plastic,

- plastic locking insert,

- screw M5-60.

Knauf Harmut has a complex structure due to which it can withstand up to 50 kg.

Knauf Harmut has a complex structure due to which it can withstand up to 50 kg.KNAUF Hartmouth is capable of supporting a weight of 55kg. In most cases, this dowel is designed for heavy objects on a drywall wall. This is a TV with a large diagonal, in the kitchen there is a shelf with dishes, in the bathroom there is a cabinet for bath accessories.

For mounting the dowel in the GVL wall, a corresponding hole is made. A plate is inserted into this gap using antennae. When the U-shaped part entered the hole, the antennae break off. A screw is screwed inside.

Universal Fisher dowel

This dowel consists of a plastic cylinder and contains a sleeve. On the side are the blades, as well as a powerful trailer. A thread for a screw is cut inside the dowel. Dowel dimensions: length - 27mm., Diameter 12.5mm.

The Fisher dowel has a plastic cylinder and a sleeve

The Fisher dowel has a plastic cylinder and a sleeveFor the installation of Fissher drywall, a hole is made, the diameter coinciding with the sleeve 12mm. Fissher is inserted into the hole made and fastened with a 6 * 50 corkscrew. When screwing the screw almost to the end, pressure begins on the conical part of the sleeve. Ultimately, under the effective pressure on the screw, the sleeve opens in different directions with blades that are pressed against the back of the GCR sheet.

For small and medium loads, the universal dowel UX is suitable. This unique form allows it to be used for fastening in drywall and other construction materials.

The dowel Fisher is sold as a set with self-tapping screws.

The dowel Fisher is sold as a set with self-tapping screws.

When attaching to a standard sheet GKL 12.5mm. fastens, say, an 8mm thick board. at the same time, the screw came out to a length of 27 mm from the back of the drywall. this indicates that there should be an empty space of 30 mm under the sheet of the gyro.

Weight with dowel - 16kg.

Dowel with spring for ceiling mounting

This type of fastener is designed for light weight. It consists of several components:

- basis - a screw with a hook,

- spacer component - 2 slats,

- clamp strips spring.

It is required to make a hole. Insert a dowel with clamping blades into it. As soon as the planks have gone beyond the boundaries of the drywall construction, the spring is activated and the planks are straightened, thereby fixing on the other side of the gypsum board.

Types of folding dowels with spring

Types of folding dowels with springThis dowel is designed primarily for hanging decorative elements and chandeliers.

If you need to hang a heavier object, we recommend using a special metal anchor and fastening it directly to concrete.

Features of the installation

Since drywall sheets are brittle in nature, accuracy in working with electric tools is required, as well as knowledge of the proper fixing of the dowel.

- To create a hole in the drywall construction, you do not need to use a hammer drill.

- If the drywall surface is finished with ceramic tiles, you need to make a hole with a diameter equal to the dowel. In this case, a drill with a special tip (victorious) is used.

- Before installing the dowel, you need to familiarize yourself with its technical specifications. Each fastener corresponds to a certain exposure in weight. If the item weighs more than the element can support, then most likely a plasterboard hole may appear in the wall or ceiling.

- Metal dowels are more expensive than plastic, nylon. But they have a long service life, and also do not deform when inserted into the surface. What often happens with plastic fasteners.

- So that the practicality of the installation of the dowel was visible, it should be fixed in profile. The frame element is easy to find using a conventional magnet.

When choosing and purchasing a dowel, you should pay attention to all the small details, its technical characteristics, the material from which it is made.

In addition, we recommend watching a video on choosing the best drywall fasteners.

Mounting butterfly dowels

Mounting butterfly dowels Molly dowel has teeth for solid surface fixation

Molly dowel has teeth for solid surface fixation Molly Mounting Scheme

Molly Mounting Scheme It is possible to purchase a sleeve with a hook in the Molly dowel

It is possible to purchase a sleeve with a hook in the Molly dowel Knauf Harmut has a complex structure due to which it can withstand up to 50 kg.

Knauf Harmut has a complex structure due to which it can withstand up to 50 kg. The Fisher dowel has a plastic cylinder and a sleeve

The Fisher dowel has a plastic cylinder and a sleeve

The dowel Fisher is sold as a set with self-tapping screws.

The dowel Fisher is sold as a set with self-tapping screws.

Types of folding dowels with spring

Types of folding dowels with spring