In this article we will consider the types of ceiling tiles. We hope that the recommendations below on the design of the ceiling will come in handy and greatly facilitate the choice.

The ceiling is an integral and important part of any room, and therefore it is so necessary to pay attention to its design and decoration.

This mysterious ceiling tile - how to choose it correctly?

With the help of ceiling tiles you can not only decorate the ceiling, but also insulate the apartment, create sound insulation and even visually increase or decrease the size of the room. Also, tiles will help to hide minor irregularities (see. Laminated ceiling tiles: installation and care).

Ceiling Tile Material

Ceiling tiles are made from a variety of materials. For example, to create good sound insulation, you can use fiberglass tiles mixed with starch.

As the material also use wood, polystyrene foam, various light metals. However, metal plates are the most expensive, therefore they are used less often..

Expanded polystyrene (or its other name - polystyrene) is the most common option. This species is popular because of its low cost and a large variety of patterns on its surface: imitations of wood, marble, metal and different colors.

In addition, it has other advantages:

- Regardless of the material, it provides additional heat and sound insulation.

- Creates a beautiful texture on the ceiling.

- After gluing, it practically does not reduce the height of the room.

- It is offered in a wide variety of sizes and terrain options.

- It is maintainable.

- It has a low cost.

The tile can be not only embossed, but also smooth with a rough or glossy surface. Often it is sold in trim levels, which also feature ceiling skirtings and sockets suitable for style. Thus, complexity in the selection of compatible materials is eliminated. Skirting boards are used to design the transition in the corners between the ceiling and walls. The socket is used to refine the part of the ceiling at the installation site of a classic hanging chandelier.

Ceiling tile is repairable. In case of damage to individual elements, they can be dismantled and replaced with new ones. In addition, polystyrene foam products can be repaired with repair putties and repainted to match the rest of the ceiling.

What is a ceiling tile

Varieties of this building material include wood panels and decorative metal sheets, but when it comes to ceiling tiles, they often mean a polystyrene version of these products.

A stack of 7 ceiling tiles.

Ceiling surfaces have been finished with polystyrene for several decades. Initially, multilayer foam slabs were used as insulation and noise insulator in industrial premises. Over time, they learned to make this material better, using new technologies in its production. As a result, it has become a suitable option for decorating in residential buildings and apartments.

There are several arguments for and against the use of foam products in the decoration of the ceiling.

- This is not the best choice, mainly because of the method of production of the material in which harmful components are used,

- The second disadvantage is the high sensitivity to temperature - even a short contact with a heated lamp housing leads to deformation and, even, destruction,

- It is believed that the foam ages quite quickly from ultraviolet sunlight, therefore, it is best to use laminated types to decorate rooms facing south and having large windows,

- The porous spongy surface of the material absorbs dust and soot very well, which cannot be removed by conventional methods.

- The main advantage of ceiling tiles is their very low weight. One ceiling product made of foam, with dimensions of 50x50 cm, weighs only 100 g,

- Products made of polyurethane foam do not darken and do not undergo degradation under the influence of atmospheric oxygen,

- They do not contain in their composition substances and compounds that can be a favorable breeding ground for fungi and bacteria,

- All kinds of stains and dust are quite easy to remove if you regularly and carefully carry out wet cleaning,

- The noise and sounds in the room are partially suppressed, the housing is perfectly insulated,

- The tile hides small flaws and roughnesses of the base and allows to do without preliminary filling,

- Low cost of synthetic products,

- In traditional applications, the height of the ceilings is maintained and the volume of the room is emphasized,

- Proper care and use of suitable adhesives during installation, allows the surface to be preserved without changing the quality of the ceiling finish for at least 10 years,

- Updating it is quite simple, water-soluble acrylic paints are ideal for this. At the same time, from such a painting, the quality and depth of the pattern or texture of the bulges practically do not change.

The use of expanded polystyrene panels for decorating the ceiling is an ideal solution for quick repairs when you need to bring a separate room to a ready-made look in a short time to live in or rent it out. If necessary, with the help of ceiling tiles you can perform high-quality and high-level finish.

Many users prefer this building material due to its accessibility, ease of installation (fixing to glue), quick preparation of the base and the quick completion of all work. With light sheets, optimal sizes (50x50) it is very convenient to manage, lay out the ceiling, fix and cut them, and a wide selection of colors and textures will help satisfy the most sophisticated taste and choose the right option for any room (kitchen, living room, bedroom).

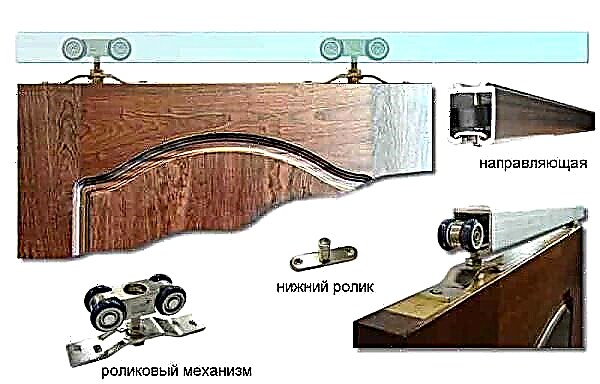

Varieties of seamless tile material

For the manufacture of seamless tiles, polystyrene foam from the foam class is used, the thickness of the finished elements can be 3.5-15 mm. The tile can have a different shape, and on its surface there is a pattern from which all kinds of patterns can easily be folded. Using seamless polystyrene tiles, you can create an imitation of wood, stucco, or artistic plaster. The edges of the tiled seamless material are made so that the seams at the joints are practically invisible and can only be viewed at a very close distance.

There are several manufacturing techniques for such a material:

- Pressing. Using a stamping press, the mass of expanded polystyrene foam takes the form of a plate with defined edges and a pattern on the surface. The thickness of the tile in this case is approximately 5 mm, and its area does not exceed 0.25 m 2. Material made by this technology is quite low cost.

- Injection treatment. To answer the question of what is an injection ceiling tile, it should be said that in this case polystyrene foam is exposed to high temperatures, as a result of which the material is sintered in molds. Tiles made in this way have increased strength and greater thickness, it can be from 8 to 15 mm. In addition, the products are distinguished by a large selection of patterns and textures.

- Extrusion. Many consumers ask the question, extruded ceiling tiles, what is it. The manufacturing process of such a material involves the addition of blowing agents to the composition of a ceiling tile under the influence of high temperature and pressure. Stripes are formed from the finished mass, on which a special protective coating is subsequently applied. Separate plates are formed from such strips. Using a protective film, an imitation of metal, wood, plaster and stone is created, while the color and texture are almost natural. The thickness of the extruded seamless tile does not exceed 5 mm, but such a material is characterized by increased strength. The cost of tiles made using this technology will be significantly higher than other types.

Depending on the shape, tile materials for finishing the ceiling surface are divided into two types:

- Straight Edge Tiles. Such products are made in the form of squares on which drawings and patterns are applied. All elements, including rectangular ceiling tiles, have exactly the same size and precisely made edges. Thanks to this, the tiles fit tightly to each other, forming a minimum gap, almost invisible from the outside.

- Tiles with complex edges. This category of materials helps to create aesthetically attractive patterns and patterns on the ceiling, since there is practically no gap when connecting individual elements with wavy edges. This gives the room a personality.

In any case, it’s important to know exactly which ceiling tiles are better.

Material

According to the material of manufacture, this tile is different:

- Woodenmade of oak, mahogany, birch, aspen, linden, has a smooth, structural and carved surface texture,

- Metalhaving a concave, convex, frosted, mirror surface (one of the most durable and refractory categories, withstanding temperature extremes),

- Plastic and polystyrene, characterized by a smooth or embossed surface, resistant to any temperature, practical, against the general background resembling gypsum stucco.

For example, wooden varieties do not have a lot of weight, so they do not create a load on the draft base of the ceiling. To counteract moisture, they are coated with a layer of varnish. Metal is convenient with a variety of designs and colors, easy to glue, but can cause difficulties with cleaning, so you have to remove dirt by diluting a special concentrated product. The classic polystyrene category (PVC) is the most demanding of all.

Dimensions

Standard sizes of ceiling tiles depend on the material of manufacture.

Each category differs in its standards, for example:

- wooden can be 30 x 30, 50 x 50, 70 x 30, 60 x 20, 60 x 60 cm,

- inherent dimensions of metal 60 x 30, 50 x 50, 70 x 30, 30 x 40, 40 x 40 cm

- polystyrene foam (solid and perforated) differs in parameters of 50 x 50, 60 x 60, 40 x 40, 60 x 30, 70 x 30, 70 x 40 cm.

These are far from all possible dimensions. It is worth considering that this material is often made to order. For example, strips of metal tiles can reach up to 2 m in length. The synthetic variety can be very small (less than 30 cm), or large enough (up to 1 m).

Colors

The days when exclusively white tiles were on sale are a thing of the past. Today in construction stores you can buy non-ferrous materials in a wide range. Among the classic shades, white-blue, light pink, delicate milk, cream, sand, coffee, gray and orange tones are noteworthy. No less interesting are mint, lilac, purple, brownish-pink paints. Among the assortment you can find unusual varieties with a metallic sheen. This group includes golden, silver, copper, brownish, swamp shades.

Such a tile does not provide for painting, while porous white is quite well stained with dye with the addition of the usual color. Any shade can be obtained by mixing two or three pigments if necessary. This allows you to adjust the color of the ceiling to the design idea of the interior of the room, if you want to replace the white color with the color.

The category that can be colored is visually thicker than the color variety.

The form

The original classic shape of the ceiling tile was a square. So it was easier to start work, calculating the center of the ceiling, or performing it from the corner. Symmetry contributes to a harmonious aesthetic perception: the ceiling seems flat and does not warp the walls. Today, in addition to square tiles, whose parameters are small, on sale you can find rectangular and non-standard material. In this case, the lateral faces can be linear or curly (for example, wavy, concave, convex).

Advantages and disadvantages

The ceiling tile has many advantages:

- it is produced on modern equipment using new technologies, due to which it differs in structure and has good operational characteristics,

- the tile has several categories that differ in the composition of the raw materials used, which can be natural or artificial,

- the material can be of different shapes, which allows you to choose various options for the ceiling decoration, taking into account the chosen style and non-standard types of ceiling zone,

- it is easy to install: it allows you to perform it efficiently due to the optimally convenient size,

- regardless of the type of material, the ceiling tile strengthens the base of the ceiling and insulates it, which is especially felt in the cold season,

- the tile is the soundproofing of the room, saving households from annoying extraneous sounds coming from neighboring apartments,

- has a wide variation of the picture, as well as the texture, which allows you to use it in the same style with the furnishings as a support for the desired picture,

- this finish has a lot of color shades, and in some varieties allows repeated surface painting with the usual color,

- ceiling tile is a universal material that can be bought at any hardware store, while it has a wide range of cladding for every taste,

- some varieties of this material are suitable for wall decoration,

- in the assortment there are varieties for which it is not at all necessary to level the ceiling to perfection,

- the material is characterized by reasonable cost, so the purchase of a large amount will not hit the family budget.

The texture of the ceiling tile is also noteworthy: it can be smooth, rough, embossed or laminated. This material is able to imitate textiles, metal and wood. It is easy to choose a skirting board, corners and sockets in this style for such tiles. Based on the type of material used, the thickness of the varieties varies from 3 to 14 mm.

This decoration fits perfectly into the interior of different rooms: it can decorate the ceiling of the living room, children's room, study, kitchen, corridor, hallway or bedroom. At the same time, for each room, you can choose varieties with a special pattern and texture. A wide range and demand are explained by the environmental friendliness and safety of many varieties of large manufacturers.

With many advantages, such a facing has several negative aspects:

- the material is not always identical: often it needs a calibration that slows down the finishing work,

- porous ceiling tiles can be deformed, so before buying it is important to consider the type of glue,

- not every type of glue can be removed from the front surface without damaging the material, so the work should be carried out as accurately as possible,

- fragments of synthetic material are quite fragile: when adjusting the angles, they can break, which increases the percentage of rejects,

- some materials do not have even angles due to the tight packing that tightens the corners and makes them blunt, which leads to the formation of cracks and voids.

The disadvantage of the porous categories is shrinkage when applied to the surface of the adhesive composition and the manifestation of glue on the front side of the cladding. Also, some varieties have a pattern in a certain direction, so often fitting joints is difficult.

Moreover, it is undesirable to stick ceiling tiles to the base of the ceiling immediately after purchase. It is prone to moisture accumulation.

So that in the future this material does not shrink, it is necessary to remove the plastic film from the packaging, leaving them for two or three days in a dry room.

How to choose

In order to choose the right tile for the ceiling, you need to decide on the overall interior of the room. In some cases, zoning is performed, where a separate part of the room has different decoration materials for the walls and ceiling. For example, in the room in which the living room is combined with the kitchen, several materials can be finished. At the same time, wallpaper is glued in the living room, the ceiling is painted, and the kitchen is finished with walls and ceilings. All materials should be ideally combined among themselves, and also with furniture.

In addition to tile design, it is necessary to pay attention to its quality, namely:

- Flatness of the edge. If it is curved, then laying the material back to back against the wall and with each other will be very difficult, and the work will look messy.

- The material in the slice should be dense. If pieces break off from it or it crumbles, then the quality of finishing with such tiles will not be at the highest level.

- The structure of the material should be uniform, with a clear pattern, if any. The presence of dents indicates that the tile is made of low-quality material.

When purchasing a tile, you can check its quality as follows: take it by one edge and shake it a bit. If nothing happened to the material, then you can safely take it. In the event that the edge began to crumble, deform, or even break off, it is better to refuse such a tile.

Ceiling tiles for the ceiling are made of such materials:

If we talk about the most common, foam, then there are its main subspecies:

- Extruded.

- Stamped.

- Injection.

Extruded the tile is made of foam and covered with a protective layer. Such material can be easily cleaned of contaminants, which significantly prolongs its original appearance.

It is difficult to stack because it crumbles easily. It is also difficult to care for. It is better not to lay stamped tiles in the kitchen and in rooms with high humidity, because it will quickly wear out.

Injection the tile has the highest strength of all considered. Such material after laying does not leave a visible seam, which allows you to create a perfectly flat surface.

How to glue the ceiling tile

The construction market offers many adhesives that are used for various purposes. To choose the most optimal options correctly, you need to operate with several criteria:

- The glue should quickly set, then you will not have to stand for a long time in a static position and hold the glued element,

- Solvents are not acceptable in its composition; otherwise, the foam will sag at the points of contact with it,

- It is important that the color of the adhesive is white or transparent - partial translucence may be observed on thin stamped sheets,

- Glue adhesion is required to adhere to a dry concrete surface,

- Since the material of the ceilings can be different (wood, concrete, OSB, drywall), it is advisable to purchase a universal product that is suitable for all conditions.

The following video discusses some options for fixing mixtures:

Acetate Formulations

Universal transparent adhesive mixtures with a pungent odor of acetone, which are sold in liquid form in transparent plastic bottles, are acetate glue. In air, acetone evaporates, and a thin layer of liquid resin hardens, firmly fixing the bonded element.

With external resemblance, various products with acetate glue have a noticeably different setting speed and can greatly delay the gluing process and tire a working person. The most effective products are titanium and dragon.

Among the most noticeable advantages of this type of glue, good adhesion can be distinguished - it allows fixing directly to whitewash.

The disadvantages are a bit more:

- The mixture does not allow masking the joints, as it is completely transparent,

- It has a sharp chemical smell, therefore it is required to carry out work with good ventilation,

- It is impossible to perform good fixation with noticeable irregularities on the base or the presence of heavy bonding elements (decorative skirting boards, injection or mirror tiles.

Wallpaper glue

All types of mixtures that are used for wallpapering can be used as fixatives for plastic panels: Bustilate, PVA, non-woven and vinyl glue. The technology for using these compounds is very similar to the process of gluing wallpapers, when glue is abundantly applied both to the product and to the ceiling surface at the same time.

The disadvantages of wallpaper mixtures are significant:

- Very long drying time. You will need to simultaneously glue and hold several sheets at once in order to at least slightly speed up the process,

- The technological features of the application are such that it is so convenient to fix only thin stamped types of tiles,

- It is not possible to mask the seams with this glue, as is the case with the acetate composition.

Acrylic putty glue

Acrylic putty meets all the requirements that apply to means for gluing ceiling tiles. It is white, quite viscous, instantly fixes and holds any plastic sheets and baseboards. In addition, with its help it is possible to mask small flaws and joints in the injector ceiling coatings.

The use of acrylic putty is somewhat unusual. It is applied with a thin putty layer on the ceiling, filling all the irregularities and defects of the base, and then, decor elements are fixed on the sticky surface.

Among the disadvantages are the following:

- Increased consumption

- High price,

- Incompatibility with color laminated panels.

Liquid Nails

The most successful option for use with plastic panels is colored fixative compounds called liquid nails. They not only perfectly fix the PVC tile, but also allow you to mask the joints on sheets of any color, just buy the glue of the desired shade.

Due to the characteristics of this product, it is enclosed in special tubes under the gun. The amount of glue required depends on the weight of the tile and, usually, a sufficient contour smear. Due to the low consumption of this product relative to the total square of the ceiling, it is not much more expensive than acetate glue.

Set of necessary tools

Laying seamless ceiling tiles on a wall or ceiling is done using the following tools:

- Building level. This device helps to determine the evenness of the draft ceiling and to verify the correct installation of individual tiles on the ceiling.

- Roulette and square will be needed to perform the necessary measurements.

- A clerical knife and interchangeable blades for it are necessary for cutting tiles to the desired size. This applies to those moments when solid elements do not fit in one row.

- In some cases, a spatula may be needed for operation. Most adhesives are packaged in tubes, but sometimes they are packed in small volume buckets. In this case, the adhesive is applied to the surface of the tile with a spatula, brush or roller.

- Marking the location of tiles on the ceiling is carried out using a pencil or marker. In addition, sheets of paper can be useful on which you can pre-sketch a future drawing or pattern.

- Well, the most important device can be called a stepladder or an ordinary table. It is simply impossible to carry out installation work on the ceiling without them.

Preparation for work

For high-quality gluing of seamless tiles, it is important to perform a number of preparatory activities on the ceiling. The main direction is cleaning the surface of the old coating, traces of dirt, grease and dust.

Depending on the material used to decorate the ceiling, a cleaning method is chosen:

- If the ceiling was glued with wallpaper, then the surface is pre-wetted with water and wait until the material becomes wet. Further actions involve the removal of wallpaper from the ceiling, using a narrow spatula for this purpose. Then remove the remaining glue.

- You can also remove old tiles from the ceiling or plaster with a narrow spatula. If the plaster sits firmly on the surface and does not fall off when tapped, then polystyrene foam tile can be glued directly to it.

- The whitewashed surface is washed several times with plain water or with the addition of detergent. Most often, an old coating of this type is removed in two to three steps.

- In the same way used to remove water-based paint.

- Old oil paint is scraped off with a spatula.

- Coloring compositions that are not susceptible to scraping or rinsing are removed using special solvents. After their use, it is recommended to thoroughly rinse the surface with water.

Further preparatory activities are carried out in the following order:

- All lighting devices are disconnected and removed, the ends of the wires are isolated. If possible, it is recommended to turn off the electricity in the room during the repair period.

- Inspect the ceiling, revealing any defects and height errors. For differences of more than 5 mm, putty is used to level the surface.

- In a similar way eliminate chips, excavations and cracks. In this case, minor defects can be left, ceiling tiles are responsible for their disguise.

- A deep penetration primer must be applied over the concrete ceiling and putty. This material provides high adhesion of work surfaces. The surface is primed several times, and each subsequent application is performed after the previous layer has completely dried.

Sticking ceiling seamless tiles

Before you start gluing seamless tiles to the ceiling, you need to know what kind of ceiling tiles are and draw up a plan of the location of the elements. To do this, with the help of a tape measure the parameters of the room are measured, it is important to remember that the room can be non-standard, so the length and width of the ceiling in different places can differ. A pattern is drawn on paper, in accordance with the resulting pattern, the number of tiles in length and width is calculated.

Next, the markup is transferred to the ceiling, here a ruler, square, marker or pencil will come to the rescue. Pre-ceiling space is divided into four parts diagonally or in the middle of opposite walls. To facilitate the markup process, you can use an ordinary thread.

The next step will be the direct installation of tile elements and their sticker. The installation process is as follows:

- Packages with decorative materials, including wood-like ceiling tiles, should be opened and left for a while. In this case, the tile takes the room temperature and is not deformed during operation.

- After a certain time, the adhesive is applied to the tiles on the back side with dots. The glue must be in the center of the tile element and along its edges. The distribution of glue on the tile with a spatula is allowed.

- After application, the liquid adhesive must be dried, after waiting a while. Most often, the manufacturer indicates such information on the package.

- The prepared ceiling tile is applied to the ceiling in the designated place and pressed with little effort. It is important to remember that polystyrene tile has increased fragility, therefore, strong pressure can damage the element. Laying of the first tiles begins in the central part of the room, and one element should be glued on each marked area.

- Before gluing, tile should be laid evenly, pressed and held for some time so that the adhesive composition grasps with the surface of the main ceiling.

- Similar actions are performed with all integral seamless injection ceiling tiles. In the process of laying, make sure that there are no gaps between the tiles. If excess glue sticks out when pressed, remove it immediately. After drying, the adhesive is removed quite difficult.

- Cut edges are laid along the edges of the ceiling.

- It is recommended to seal the joints of the elements with acrylic sealant. You can use a silicone compound for this purpose, but it may acquire a yellowish tint during use.

Using a beautiful ceiling tile made of polystyrene foam, you can make high-quality and inexpensive repair of the ceiling, and the right choice of material helps to increase its service life.

Pressed

The work uses the press method, or stamping. As a material, an expanded polystyrene block is excellent. After pressing, articles with a thickness of 6-8 mm are formed.

p, blockquote 6.0,0,0,0,0 ->

- Low cost.

- Low strength.

Extruded ceiling tile p, blockquote 8,0,0,0,0 ->

Extruded ceiling tile p, blockquote 8,0,0,0,0 ->Panels of this type are porous and loose, which is why dirt easily gets in and cannot be washed off.

p, blockquote 9,0,0,0,0 ->

Wet cleaning is contraindicated for such ceilings, since they are covered with water-based paint.

Injection

They are much better in quality than the previous ones. To create, the method of sintering of polystyrene foam raw materials is used. Injection tiles on the ceiling have a thickness of 9 to 14 mm. The drawing on it is clear, deep, with the correct geometric shape.

Injection ceiling tile p, blockquote 11,0,0,0,0 ->

Injection ceiling tile p, blockquote 11,0,0,0,0 ->

Injection panels allow you to create a seamless ceiling.

p, blockquote 12,0,0,0,0 ->

The positive characteristics of the tiles on the ceiling can be called:

- excellent sound insulation

- moisture resistance

- fire retardancy,

- environmental friendliness

- excellent durability.

Extruded

For its manufacture, an extruded polystyrene strip is used, which is obtained by pressing. Such a strip may be painted or film coated.

Here is the extruded tile p, blockquote 14,0,0,0,0 ->

Here is the extruded tile p, blockquote 14,0,0,0,0 ->

The characteristic features of this species are:

- lack of grain

- smooth surface,

- high strength

- reliability,

The pros can be called:

- high hygiene properties

- protection against dust, water.

It is easy to care for such a ceiling; moreover, it is easy to restore it after deformation. He obtained these properties by coating the consumables with a film or special paint.

Extruded tile can be decorated with p patterns, blockquote 17,0,0,0,0,0 ->

Extruded tile can be decorated with p patterns, blockquote 17,0,0,0,0,0 ->

Strong exposure to sunlight can cause yellowing of the panels.

p, blockquote 18,0,0,0,0 ->

Equally smooth the edges of the decorative coating, which should remain so even after cuts. Extruded panels are manufactured using certain technologies. Due to this, their edges are rounded down, this helps to hide any irregularities.

p, blockquote 19,0,0,0,0 ->

This type of ceiling tile has many colors and patterns, but it is not recommended to paint it.

For the most part, when working with ceiling tiles, the following sequence of actions will be required:

- Alignment of the draft ceiling.

- Primer surface.

- Sticking tiles and skirting boards.

- Painting.

So that after laying the tile does not look like steps and holds firmly, it is important to install it on a flat base. To do this, if the rough ceiling has irregularities, they should be leveled with plaster or putty. In this case, the plane itself does not need to be perfectly smooth. If it is rough, then the glue can hold the tile even stronger.

If there is whitewash on the ceiling, then it must be removed. It is most convenient to do this using steel putty knife. To facilitate the process, the whitewashed ceiling can be moistened with a spray bottle.If you use grinding machines, you need to be prepared for the formation of a large amount of dust.

Sticking tiles is possible on almost any ceiling. It can be made of drywall, concrete, wood, chipboard, OSB-plates. At the same time, it is important that the glue used for this purpose accurately has adhesion to such surfaces.

In order for the glue to hold firmly, the base must be primed. After this, the ceiling is marked so that the tiles are glued symmetrically. It is recommended to glue the first of them in the center of the room and then lead all the rows from it. In this case, the wire for the chandelier will come out of its middle. You can also lay 4 tiles so that the center of their adjacent corners falls on the center of the room. In this case, the cable for the chandelier comes out between them.

Ceiling tiles are usually glued onto a composition of liquid nails. At the same time, a special variety is used for polystyrene foam. It is important that the glue is white, as thin tiles often shine through. As a result, if the composition is beige, then it is visible as dirty spots. Wash liquid nails that have fallen on the front surface in a timely manner.

All tiles are glued together end to end. Between them should not form such a seam, as when laying tiles. First, whole tiles are laid, and at the end, clippings are made under the walls.

Since most polystyrene tiles are used, they need to be painted. To do this, it is better to use paint of the 1st class of resistance to washing. In this case, the product can be wiped with a damp rag.

Pros of ceiling tiles

If we talk about the general advantages of using products of this type, then it is worth highlighting the following points:

- The quality of the tiles. It is made by several methods using modern equipment.

- Big variety. This applies not only to the shapes, colors and sizes of products, but also to their composition. For example, you can install synthetic or natural tiles.

- Possibility of use for rooms with a non-standard layout.

- The tile has noise insulation properties, so you can reduce the sound level from the apartment above.

- Acts as an additional heater. This is especially noticeable if you live on the top floor.

- Suitable for most rooms.

- Does not require serious ceiling preparation. If there are minor irregularities and defects on it, then the ceiling tile will hide them.

- Durability. The service life of such a coating is more than 10 years. Even if over time the tile has lost its former gloss, it can be updated without problems by coating with paint.

Ceiling tile has an affordable price (one element may cost from 20 rubles). In fact, this is a good alternative to drywall constructions and suspended ceilings. But tile work is much simpler. Due to the fact that the products weigh a little, the installation significantly reduces the consumption of glue. It can be applied not on the entire surface of the plates, but pointwise.

But despite all these advantages, it was not without a fly in the ointment in a barrel of honey.

Disadvantages of ceiling tiles

If you highlight the main disadvantages, then there will be few, but you should know that:

- Sometimes tiles need to be trimmed, since fragments quite often do not match each other in length. Faces can also be jagged.

- If glue gets on the surface of the tile, there is a risk of damage to the element during its removal.

- If you prefer synthetic tiles, then you will have to cut it extremely carefully. Such products often break corners and edges.

- When using tiles with a more porous structure, possible shrinkage should be considered. Therefore, glue will need to be selected carefully.

Also, some tiles may bend due to careless storage and not return to their original form. However, much depends on what, and by which technology, the products are made.

Laminated

To create such panels, a special, laminated coating was used. Due to this, it can have different colors. In addition, such panels are not afraid of excessive moisture.

p, blockquote 22,0,0,0,0 ->

Laminated tiles in a classic design

Laminated tiles in a classic design

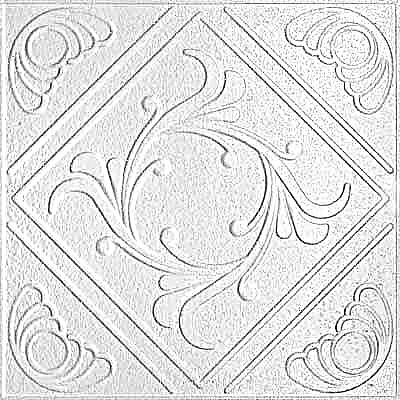

Seamless

Modern panel technology has allowed the creation of a seamless ceiling. Seamless webs allow you to quickly recreate the design. In toga, you get a seamless ceiling.

p, blockquote 24,0,0,0,0 ->

p, blockquote 25,0,0,0,0 ->

Seamless tile looks like stucco

Seamless tile looks like stucco

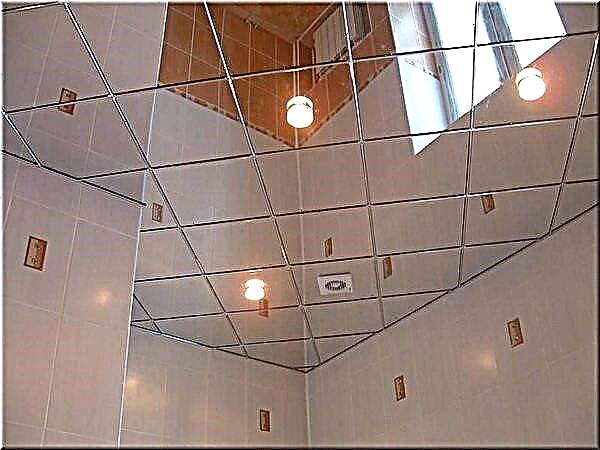

Mirror

For the manufacture of such panels, plastic is used, on the front side of which a mirror relief is applied. The shape of the tile can be square or rectangular. Thanks to such a ceiling, the space visually expands.

p, blockquote 27,0,0,0,0 ->

p, blockquote 28,0,0,0,0 ->

Mirror tile looks spectacular h2 2,0,0,0,0 ->

Mirror tile looks spectacular h2 2,0,0,0,0 ->

Pros and cons of ceiling tiles

Any finishing material has its positive and negative characteristics. Among the advantages of the ceiling slab are:

- low cost

- the ability to mount on any surface,

- hides bumps in the ceiling

- quick and easy installation

- You can install it yourself, without the help of specialists,

- the product is thin, light,

- large selection of colors,

- high-quality polystyrene is not subject to burning.

- most species have low moisture resistance,

- because of the sunlight, such a ceiling quickly turns yellow,

- subject to damage

- in most cases, seams are visible.

Ceiling panels come in many colors and designs. H2 3,0,0,0,0,0 ->

Ceiling panels come in many colors and designs. H2 3,0,0,0,0,0 ->How to care for such a ceiling

In order for the decorative ceiling to last longer, the following rules must be observed:

- Such a ceiling should be periodically vacuumed. This will help remove excess dust and increase the time between wet cleanings.

- For washing, it is better to choose products with low abrasiveness. Do not use too aggressive products.

- Stamped tiles must not be washed.

- Grease stains can be removed with alcohol.

How is tile fastened

From what materials it would not be made, the process of its fastening will be the same. At the beginning of the work, you need to calculate how many panels you need to purchase, the amount of adhesive will depend on this. Its standard sizes are 50 * 50 cm.

p, blockquote 38,0,0,0,0 ->

When choosing glue, you should not save, because the reliability of fastening depends on this. The most common types are: Moment, Titanium, Eco-naset. To work, it will require an adhesive gun, with which this composition will be applied to the tile.

p, blockquote 39,0,0,1,0 ->

The surface on which the tile is mounted must be level, otherwise the void may cause air to enter. Consequently, the structure will begin to collapse.

p, blockquote 40,0,0,0,0 ->

For mounting the structure, transparent glue h2 6,0,0,0,0,0 -> is used

For mounting the structure, transparent glue h2 6,0,0,0,0,0 -> is used

Who produces the ceiling tiles

The main manufacturers of ceiling tiles is the company:

- Antares (Russia), which manufactures stamped, injection and extruded panels.

- Lotus, which are produced in Russia. Usually it has a white color, relief and a laminated surface.

- Kindecor (Russia) - these panels have many advantages, among them: the correct geometric shape, the absence of gaps, etc.

- Matrix (China) - it is used for suspended structures. The resulting products are thinner than those manufactured in Russia. However, such designs have an excellent appearance. However, they are presented only in white, other color palettes are not used.

- Orbits (Germany) - such panels have a high moisture resistance, which makes it possible to use them for the bathroom.

- Angara (China) - such a product is in great demand. Its advantages are low cost and quality.

- Dune (EU countries) - such panels are thicker than Chinese, so their cost is much higher.

How is tile made

Ceiling panels are produced in three ways:

- Pressing or stamping. Using a press, large foam boards are compressed and compacted. The thickness of such products is 0.7-0.8 cm.

- Injection method - panels are made in a special mold under the influence of high temperatures. Products are thicker and stronger (1.4 cm).

- Extruded method - in this case, the products are very thin, about 2.5 mm. However, their strength is quite high, and all thanks to the glued coating.

Decorative elements that are installed on the ceiling can be embossed, smooth, laminated, white or colored on the front side.

p, blockquote 44,0,0,0,0 ->

To get a seamless ceiling, panels for this need to be selected with a special relief formation at the edges. This makes it possible to easily connect the parts, and the gaps between them will not be visible.

Ceiling tile can go without gaps p, blockquote 45,0,0,0,0,0 ->

Ceiling tile can go without gaps p, blockquote 45,0,0,0,0,0 ->

For the installation of panels you will need quick-drying glue.

Tile installation

It’s not so easy to work with polystyrene, all calculations must be accurate, and the slices must be neat.

p, blockquote 47,0,0,0,0 ->

For installation, you must perform the following steps:

- Make the ceiling perfectly smooth, clean from dirt and old coatings.

- Adhesive for work is better to get white. Transparent - less quality and inconvenient to use. In this case, the panel will have to be pressed strongly against the ceiling and held for a long time so that it sticks.

Installation of ceiling tiles must be done according to the rules p, blockquote 48,0,0,0,0 ->

Installation of ceiling tiles must be done according to the rules p, blockquote 48,0,0,0,0 ->As the adhesive, you can use the finishing putty.

- All necessary tools must be prepared in advance.

- Marking the ceiling must be done carefully, carefully calculating everything. This is done as follows: diagonals are drawn, places of their intersection are marked. Further, the midpoints of the opposite sides are connected by segments. All the resulting lines should connect at one point, this is the center of the room.

It is in the center of the room that there should be a chandelier.

p, blockquote 50,0,0,0,0 ->

To lay the first rows of tiles, you need to draw perpendicular lines. You should start from the center and to the edges.

- The first two panels should be connected by corners in the center, a cord from the lamp will pass through them. For this, the corners can be trimmed a little. The remaining plates are glued in a spiral around the first two.

All rows and posts should be parallel.

- So that the seams are not visible, they should be sealed with sealant.

Ceiling panels do not lose their popularity. Thanks to new technologies, design, new colors and reliefs of the product appear. In order for such a ceiling to serve for many years, the installation and maintenance rules must be observed.

According to the manufacturing principle

So, let's figure out what happens with ceiling tiles.

- Pressed tile (stamped). In its production using the stamping method. The basis for the manufacture of this type of product is polystyrene foam blocks.

Due to the pressing effect, articles are formed whose thickness is 6-8 mm. This tile is one of the cheapest options, which, unfortunately, does not have high quality indicators. Its porous, loose surface without any coating easily absorbs dirt, which is then very difficult to wipe off..

Also, it is categorically not recommended to wash, although you can paint it with a water-based paint. It is better to buy this tile with a margin, since it is too fragile and brittle, and when cutting it, it is extremely difficult to achieve even edges (see Ceiling painting with water-based paint: process features).

- Injection tiles. In its manufacture use the method of sintering polystyrene raw materials. As a result of high-temperature processing, tiles with a thickness of 9-14 mm are obtained, with a clear and rather deep pattern, as well as the correct geometric shape.

Such tiles are much thicker than their "brothers". Using a tight joint of the edges, using this tile you can create a ceiling "without seams."

Injection tiles are characterized by good heat and sound insulation properties, are not afraid of moisture, do not burn, are environmentally friendly and have good strength. It is made exclusively in white, but it can be painted.

The disadvantage of injection tiles is its price: it is three to four times higher than the price of stamped tiles.

- Extruded tile. In this case, the workpiece is an extruded polystyrene strip, which is formed by the pressing method. The strip can be painted or coated with a film.

A feature of this type of tile is the lack of graininess, and therefore its surface is completely smooth. Extruded tile - the most durable, most reliable, but also the most expensive.

One of its main advantages is its good hygienic properties. Its surface is dense, smooth, protected by a dust- and water-repellent film, therefore it is perfectly washable and can perfectly recover after deformation.

In this type of tile, squares are perfectly cut, and at the same time an even edge is created. The edges of the tiles are slightly bent down, so a cavity remains on their back side, which allows you to hide minor irregularities in the ceiling. This type of tile can be of various colors, as well as with patterns and without them. But painting it again is strongly discouraged.

Note! Before sticking the ceiling tile, you need to clean the ceiling well, and even trim it if necessary.

Remember! Under the influence of time and sunlight, the extruded tile may turn yellow.

Advice! If you decide to use a stamped tile, before gluing, place it for three days in a warm and dry room - so excess moisture will finally evaporate from it. Otherwise, the tile can "sit" on the ceiling, and then the appearance of cracks is inevitable.

By surface type

In addition, the types of tiles can be combined by surface type:

It has a special coating - lamination. Due to this, the tile has a variety of colors, retains brightness longer and has the property of moisture resistance.

The most convenient and simple, it has absolutely even edges that do not have a border, so it is just so nice and easy to glue. Another plus is that the docking zone of such plates is almost invisible (see. Seamless ceiling tiles: installation and characteristics).

- Mirror

This tile is made of plastic, applying a mirror layer on the "front" side. It can be either square or rectangular. One of its features is the visual expansion of space in small rooms (see. Mirror ceiling tiles: types and features of installation).

Wooden

This type of tile is less commonly used due to its high cost. Products of this type can be made of linden, birch, oak, mahogany. They do not have a serious load on the draft ceiling, are environmentally friendly. As a rule, wooden plates are varnished, so you can not be afraid that they are saturated with moisture.

Metal

Products of this type can be of very different shapes, matte, metal, mirror. The main plus is fire resistance, so the elements can be installed in rooms with sharp temperature changes.

However, if the surface of the product is contaminated, then you can not just wipe it with a wet rag. Have to use specialized concentrated products. In addition, it is worth noting the impressive weight of the tile. Because of this, metal models are used less often.

It is also worth considering what the top layer of products consists of. The ease of use of ceiling tiles will depend on this.

Surface types of ceiling tiles

Based on this parameter, the tile can be:

- Laminated. In this case, a protective film is applied to the product.Thanks to this solution, the finished product can be of various colors, which do not lose brightness for a longer time. In addition, the lamination gives the tile moisture resistance, makes it smooth.

- Seamless. This is the best option for cost and ease of installation. Such plates differ in perfectly even edges, so nothing will have to be customized. It is also worth noting the stylish appearance of the ceiling and a wide variety of textures and color schemes.

Useful! Although the seamless tile looks very interesting, it is worth considering that it does not allow air to pass through. For floors of high-rise buildings, the lack of vapor permeability is so critical, but in a country house, problems can arise. If you interrupt the air exchange, this can cause condensation to form above the ceiling itself.

- Mirrored. In this case, a mirror layer is applied to the plastic product, which visually allows you to increase the space of the room. Therefore, this option is perfect for a small room. However, such models are expensive.

Therefore, the purchase of ceiling tiles should be approached responsibly.

What to look for when choosing tiles in a store

When buying such a finishing material, you need to pay attention to:

- Density and strength of the product. Checking this out is very easy. Grab the tile with two fingers at the very edge and hold. If it does not break off, then the tile will not bring unpleasant surprises.

- Geometry. The corners of the tiles should be 90 degrees, not bent or dented. All faces are smooth, without waves. Otherwise, after laying the products you will see very ugly gaps.

- Styrofoam. Evaluate the structure of the product. Foam grains should be the same throughout the tile area. The smaller the granules, the better. This indicates a good density of material, which will crumble less.

- Drawing. It must be clear, dents and other defects cannot be seen on the relief. This is very striking after installation.

It is also worth paying attention to the features of caring for ceiling tiles. In order not to regret the purchase, you will have to carry out proper surface care. From time to time you will have to vacuum the ceiling or wipe it with a damp cloth (depending on the specific material). By the way, for wet cleaning it is not recommended to use compositions in which a high rate of abrasion. It is necessary to exclude aggressive chemical fluids.

Useful! If unpleasant greasy spots have formed on the surface, then you can try to carefully remove them with alcohol.

In custody

It is important to pay attention to the manufacturer of ceiling tiles. According to customer and expert reviews, the best products are offered by Decomaster (South Korea), NMC sa (Belgium), as well as Kindecor (Russia). Ceiling plates from these manufacturers meet all the requirements of safety, environmental friendliness. It’s easy to work with the material, and the finished coating looks very beautiful. When it comes to extruded boards, Armstrong, Decoplast, Ophelia and Martin-Plast are also credible. They also offer quality products at an affordable price.

Criteria for choosing a ceiling tile

So, how to choose a ceiling tile and not make mistakes:

- Firstly, you need to pay attention to the geometric dimensions of the tile - it should have a clear square shape with angles of ninety degrees and with smooth edges. In addition, you need to pay attention so that the corners of the tiles are not rounded or jammed. Any deviation indicates that such a tile after installation may form large gaps.

- Secondly, the density of the material. Foam grains should be the same size, and the smaller they are, the better. Look carefully at the edges of the tile - they should not crumble and crumble.. The density of the material should be uniform throughout the area of the tile.

- Thirdly, a drawing - it is necessary that it be embossed and clear, without dents.

Advice! Take the tile around the corner and shake it a bit. If the edge does not break under its own weight, then the material is good. Otherwise, it is better not to buy a tile.

And yet, when buying, you need to consider not only which tile is better, but which one is best for you.