Very often, designers offer to make flooring in a room from different materials. It not only looks beautiful and modern, but also comfortable. For example, a kitchen can be divided into two zones: a work room, which is laid with ceramic tiles and a dining room, covered with linoleum. You can also divide any other room. But in order to look aesthetically pleasing, you need to know how to combine linoleum and tile unnoticed. This is what we will talk about in our article.

Linoleum and tile in one room

Linoleum and tile in one room

Types of connecting materials

To join such different materials as tiles and linoleum, you can use special sills that can be made of MDF, plastic, cork base or metal alloys. They are available in a wide range of types, shapes and colors, so picking up a product suitable for you will not be difficult.

Powder from MDF

Powder from MDF

But this is what concerns the direct junction. If the flooring has a more rounded, zigzag or other shape, then it is better to use a flexible profile. With them you can connect absolutely any configuration and even the joint of surfaces that are at different levels.

There is also a cork compensator, having a thickness of 1 cm, but capable of changing it to 5 mm to narrow or expand. During installation, it will be necessary to align all the edges, and insert the compensator deep inward so that it is not visible from above.

Since linoleum and tile can be joined without any adaptations, an ordinary sealant is perfect for this.

Tasks and requirements

Before you start joining linoleum and tile, set yourself the main tasks that must be strictly observed:

- Create a color combination. There are two options: all materials have the same tone or, conversely, are very contrasting.

- Ensuring smoothness at height differences. The height difference should look natural.

- The fixing of the flooring to each other should be very durable, it is important for heat resistance, sound insulation and moisture resistance.

When buying connecting material, pay attention to the quality of the goods. If you chose a nut, then make sure that the fasteners are carefully hidden, and its size strictly meets your requirements. An excellent solution can be the T-shaped shape of the nut, which tightly connects the cover and presses it to the floor at the proper level.

Nut and profile connection

How to dock linoleum and tile with an aluminum nut? This can be done in an open way. If the rough foundation is not concrete, then just attach the connector (already with holes) and drill the floor, strengthen and finish. If the floor is concrete, then in the measured places, make the corresponding holes and with the help of the dowel, strengthen the plate.

You can buy a door sill, consisting of two slats that attach one to the floor, and the second on top. Moreover, only the bottom is strengthened, and the front only snaps into place with a special device. This method is called hidden.

Since the height between linoleum and ceramic tile is completely different, there are two ways to level it. You can slightly raise the rough base, pouring it with a solution. Only in this case you will need to clearly measure the distance where one of the coatings that is thinner than the other will lie. It is this area that is poured with the mixture.

There is an easier way, for example, under linoleum to put a measured sheet of plywood as a substrate. When laying it, provide a place to install the profile.

To simplify the installation of the nut, first you need to cut out a recess in plywood, into which one edge of the profile is inserted, and the other is slipped under the tile. This is the easiest way to install.

Video on how the connection threshold is used:

Profiles can also be fixed directly to the floor using spot fixing. That is, not along the entire length, but at a distance of 40-50 cm from each other. If the area is bent, you will have to connect the profile to the floor at a distance of 15-30 cm.

Adhesive joint

It seems to many that joining two different floor coverings with a sealant is much easier, but it turns out not. How to join linoleum and tile with adhesive, we will tell you in detail. Initially, it is necessary that the floor covering be laid in such a way that linoleum slightly covers the tiles. When one and the other sticks well, make a cardboard template that repeats the shape of the joint. Further, this template must be attached to the over lying linoleum and outlined with a pencil. Then cut off the excess.

In exactly the same way, the cut line of linoleum is applied to the tile, which is also carefully trimmed. In order to make it easier to saw the tile according to the pattern, do not apply glue along the edge of linoleum, but leave some free space. Then after the last pruning, glue linoleum.

You can use sealant to dock

You can use sealant to dock

It is worth paying attention to the fact that no matter how you stack linoleum, you still need to glue 10-15 cm from the joint. When the joints are completely ready, apply silicone or sealant glue between them and wait until they are completely dry. Make sure that the adhesive does not hit the surface too much. Next, you need to wipe the seams with special grout for tiles and clean the surface.

Now you have complete information on how to join linoleum and tile, so, following our recommendations, you can perform the job efficiently and correctly.

How to combine different floor materials?

In order to beautifully combine two different floor coverings in one room, it is better to use special thresholds. They can be made of various materials. Nowadays, aluminum cans are relevant, as well as plastic. Some people prefer wood-type sills; they can be made of plywood. A person can choose a suitable shape and color. The stores offer a wide range of different threshold variations. As a result, you can create the perfect joint.

When the coating has a semicircular shape or in some places there are waves, it is better to put a metal profile at the junction. It is great for floors of different levels. Many are interested in how to dock linoleum with your own hands without a nut. To do this, stock up on sealant.

The advantages of combining two flooring

Before docking linoleum and tile, you should find out all the pros and cons of this kind of combination.

The selected design allows you to use the features of each material in the right places. Often the floor load is different in different areas of the apartment. When people ask how to dock linoleum and tile, designers are advised to first determine the zoning of the room and find out what the load will be on each site. In the kitchen, there is a high probability of contact of the floor with water and cleaning products. In this room, it is better to use tiles. She is not afraid of water and is resistant to mechanical damage.

Linoleum is a material that gives off heat. Therefore, if you lay this cover in the dining area, then the legs will not be cold. Tile without additional heating is considered a cold coating. Linoleum is convenient to lay, and it is easy to care for it during operation.

The main plus of the combined floor will be that it is convenient to use the tiles in the cooking area, and linoleum in the dining area. The result is a comfortable floor covering for the feet and an original design. Plus, this combination is not very expensive, unlike laminate and parquet.

Even a novice in the repair business can work with these materials. You can independently choose colors suitable for each other.

What to consider when choosing a material for flooring?

To make the perfect floor, you need to choose the right materials. An important point is the choice of colors. The floor can be made of the same color or played in contrasts. People start from the general style of the apartment.

Some people prefer to make multi-level floors using different materials. In this case, the main task is to obtain a smooth transition between levels. If it is possible to make the transition not striking, then the work was a success. The optimum height should be such that there is no discomfort during the passage of the room.

Nuances with mounts

Before joining the laminate and linoleum, you should correctly choose the fasteners. This is an important point. Many do not know how to properly stack linoleum with each other. This issue is also solved by special fasteners.

All elements of fasteners must be of high quality and reliable. Various rubbish should not fall into the space at the joints. If the work is done carefully, the floor will get good sound insulation, and will also be resistant to water. When choosing sills, it is important that the fastener location is not visible with the naked eye.

Before docking linoleum and tiles in the hallway, you need to choose a suitable threshold. An ideal option would be a T-shaped threshold. It firmly fixes linoleum and tile, creating an ideal surface.

What are the docking methods?

Some do not know how to mix linoleum and tile beautifully. The process can occur in many ways. Each of them is distinguished by its installation features. The following are distinguished:

- Using a profile and a nut. Most often, the aluminum threshold helps people out. It is installed on the joint and fastened to the floor with special fasteners. To do this, you need a drill with a drill of the desired diameter. If the floors are concrete, then after work is necessary to strengthen the work surface with dowels.

- You can choose a spade, which consists of two bars. One plank is attached to the surface of the floor, the other on the floor. The lower bracket is being installed. In order to fix the upper bar, additional tools are needed. Everyone can combine linoleum and ceramic tiles with a nut. This method is good because it allows you to hide the slice. For this he was called hidden.

- Leveling the floor. It must be remembered that tiles are most often thicker than linoleum. Therefore, before docking linoleum without a nut, you need to make the floors of the same level.

Coating alignment options for combining linoleum and tile

For this, some prefer to fill the floor with a special solution. For successful work, it is necessary to mark the place where the linoleum will be located, and pour the floor to a certain mark.

You can make the same level of coverage with a plywood sheet. It must be laid on the floor, along the junction of the coatings.

To make it easier to mount the threshold, you can make a recess in the plywood sheet. Install one part of the profile in it, the second part must be fixed under the ceramic tile. For a person who has not previously encountered repair work, this method is more suitable than others.

Profiles are best set using the spot mount method. It is necessary to withstand distances from each other of 30 centimeters. If the surface has irregularities, then the profile is mounted about 20 centimeters from the floor.

How to glue linoleum and ceramic tiles together gluefully?

Nowadays there are many supporters of sealant. People believe that with its help it is easy to fix different floor materials. This statement is not entirely accurate. To answer the question of how to dock linoleum with tiles, you need to make every effort and do the work so that linoleum covers the tiles. When the materials adhere well, make a template out of plain cardboard. It is needed in order to repeat the shape of the joint. The model of the joint is placed on linoleum. You need to draw a pencil around the contour and remove the excess. A careful cut should be done so as not to spoil the general appearance of the room.

To make it easier for a person to work, it is better to apply a sealant, stepping back from the edge. After the final trimming, it can be glued. This method is convenient to use if you need to "walk" with sealant in the corridor near the doors.

Do I need to glue joints?

A person can choose any installation method, but the joints will have to be glued. You need to choose the moment when the joints are ready. Glue is applied to them, after which it is necessary to wait several hours until the glue “seizes”. In this work, special care must be taken. The glue should not get on the tile, otherwise it will be difficult to remove it from the surface of the tile. The seams must be grinded using grout, the tone of which is selected depending on the color of the tile. At the end of the work, you need to clean the floor and fully evaluate the result.

Types of linoleum

The key to long-term operation of linoleum is its proper installation. Coating will last more than one year. Therefore, it is important to know how to dock linoleum with each other. In order to cope with this work, it is necessary to understand the types of material.

The combination of the two "pieces" will depend not only on the styling technique and skills of the master, but also on the type of material.

The following types of coatings are distinguished:

- Commercial linoleum. It differs in its thickness. This material is quite durable. Due to its thickness, joining the parts will be difficult. If the work is done correctly, the coating will last a long time.

- Household is much thinner than commercial. The front layer of this coating with a thickness of 0.1 mm to 0.3 mm.

- A semi-commercial type is also distinguished, the top layer of which has a thickness of 0.4 to 0.5 millimeters.

The composition of linoleum

Many people coming to the store for linoleum do not know that it consists of several layers. There are three of them:

- The top layer is called the front. What is the top layer made of? It is made on the basis of PVC. Its life will depend on the thickness of this layer.

- In the middle is a layer, which is a layer. It consists of a reinforcing mesh. It is made of fiberglass.

- The bottom layer is also called soundproof. It also provides thermal insulation. For it, PVC foam is used.

Most often, a special varnish is applied on top of linoleum. It gives shine to the coating, and also performs protective functions. It resists external influences.

How to dock a coating with a pattern?

Before docking linoleum with each other, it is necessary to determine the color. Nowadays, the market offers a wide range of different colors of flooring. Drawings may resemble wood floors or carpets. There is linoleum that looks like a tile. It is important that the selected material matches the overall interior design in color.

It should be noted: if a person chose a complex pattern for flooring, then you need to try to match the picture in places where there are joints. To do this, you should buy more material than anticipated according to initial calculations. You need to be prepared that you have to spend more than planned.

Docking methods for different linoleum

When professionals advise how to properly stack linoleum, they suggest the use of two methods:

- Overlap. The disadvantage of this method is that if water gets under the coating, then there will be dampness. Mold may appear. There may be a protrusion on the floor due to the fact that the coatings overlap each other. A peculiar step can interfere with walking. The floor will no longer be perfectly flat.Dirt and debris will fall under the cover. And this will complicate further cleaning.

- Butt-to-butt is considered the most successful flooring method. When working, it is important to avoid the ingress of dust and dirt between the sheets, as well as to prevent the penetration of moisture.

Why try to join individual sheets?

Sometimes people wonder how best to stack linoleum. Some see the need to combine separate sheets. This is explained by the fact that people want:

- Achieve the integrity of the coating, improve its appearance.

- Get perfectly flat floors.

- Protect the floor from moisture and contamination.

- Protect the basement from excess moisture if people live in a private house.

What are the types of joining seams?

People are often interested in how to dock linoleum using improvised tools. There are four options:

- You can use double-sided tape if it is at home.

- It is good if there are partitions or sills. They are easy to install on their own.

- There is a special adhesive designed for cold welding. It is perfect for this kind of work.

- Professionals prefer to use hot welding. They use a special cord.

How is cold welding of linoleum?

You should learn how to dock linoleum using the cold welding method. The joint must be glued with a special composition intended for flooring. He firmly connects different canvases. Please note that this glue is toxic. It is necessary to remember safety measures during the work with it. It is recommended to ventilate the room, otherwise the person runs the risk of poisoning in vapors that releases glue.

This method is good to use for independent homework. Glue equally easily connects commercial linoleum, as well as household. It should be noted that the cold welding method cannot be used for coating with a felt layer.

Distinctive features of hot welding

The hot welding method should be used when docking commercial linoleum. The seam is neat, although noticeable. It is distinguished by its quality. For welding, you need a special tool, which is usually only available to professionals.

A special burner is turned on, under its influence, the filler cord begins to melt. It is usually made of PVC. In the molten state, it completely fills the joint. Welding is carried out at high temperatures, from 350 to 400 degrees. When the coating hardens, the excess is removed with a special knife.

To obtain the perfect seam, you first need to glue the material well, and also cut a niche in the shape of the letter V. The resulting ditch must be cleaned.

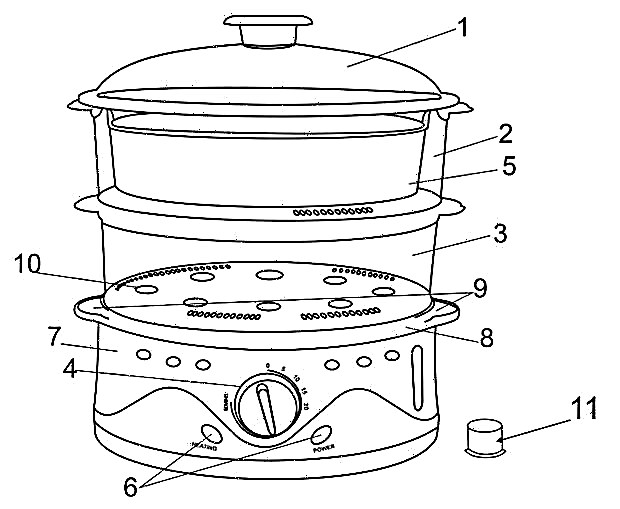

Varieties of materials

To unite the space with the help of two opposite materials, it is necessary to use special sills. They can be plastic, aluminum, consist of wood plywood or cork compensator. They are produced in huge quantities, various in appearance, shape and color, which allows each customer to choose the perfect option for creating a joint.

If the flooring is a semicircular, wavy or other shape, then a metal profile is well suited.

With it, you can combine different forms of floor materials, including multi-level floors.

Cork base is able to change its thickness, tapering and expanding. When installing the compensator, it is necessary to stick it firmly into the depths so that it cannot be seen. Joining ceramics and linoleum is possible without additional fasteners. In this case, only sealant can be used.

Advantages and disadvantages of combined coatings

In modern apartments, you can often find combined flooring. This design method allows you to rationally use the unique qualities of each material, because the load on the surface can vary greatly. Often he is found in the kitchen-living room, and sometimes in the hallway.

The load can be carried out not only due to furniture, but also in contact with water, dirt or chemicals. For such areas, it is ideal to use tiles that add surface strength and resistance to mechanical stress.

The main advantage of linoleum is its ability to give off heat, which is important for the dining area.

In addition, it does not have as many threats as there are in the working part of the kitchen.

Another plus of combined coatings is cost savings. Linoleum and tile have a low cost, unlike laminate and natural wood.

These two materials are easy to work with., therefore, the task of combining can be handled independently. The colors of the coatings are so diverse that you can easily choose the right tones.

Installation Rules

Any work requires special training, and therefore, starting the connection of tiles and linoleum, it is necessary to adhere to some rules. Without basic knowledge in the construction field and without skills in working with tools, it will not be possible to create the perfect floor.

When choosing flooring, it is important to consider their color scheme. They can be the same shade, and can be contrasting to each other. It all depends on the general style of the interior and the purpose of the materials.

If the floor is planned to be made multilevel, it is necessary to ensure a smooth transition. It should look as natural as possible and not catch the eye.

The height should be such as not to cause discomfort when moving around the room.

When installing flooring, you should carefully monitor the quality of fastening. It should be reliable and even enough so that water and debris do not enter the gap. Qualitatively done work guarantees the floor heat and sound insulation and water resistance.

When buying connecting elements, it is important to pay close attention to their quality. If a sill is chosen, then you need to make sure that the fastener places are not visible, and its dimensions are equal to specific requirements. The best option is the T-shaped threshold, which reliably combines linoleum and tile and firmly fixes them to the surface.

By means of a nut and a profile

The aluminum threshold will help connect the two materials. To do this, you only need to attach the connector with the finished holes and drill it to the floor. But if the base consists of concrete, then you need to measure the attachment points, make holes, and then strengthen the plate with a dowel.

You can purchase a door sill, which will consist of two slats. One of them should be fixed to the floor surface, and the other on top of the cover. In this case, only the lower bar is mounted, while the upper one is fixed using a special tool. This method is called hidden, because it allows you to hide the slice.

Ceramic tiles are thicker than linoleum in thickness, so when installing them must be equalized.

To do this, you can fill the floor with a solution to raise the rough base. But for this, it is necessary to carefully measure the distance in the place where the linoleum will be located, and pour the solution strictly to a certain level.

There is the simplest leveling method - a substrate in the form of a sheet of plywood. For its installation, it is necessary to provide in advance a place for fixing the profile.

To simplify the installation of the nut, you need to make a recess in the sheet, into which one end of the profile is subsequently inserted, and the second is fixed under the ceramics. This method is preferable for a beginner.

Profiles can be fixed to the floor by means of spot fixing. That is, not on the entire surface, but at a small distance (30-35 cm). If there are bumps on it, then it is necessary to fix the profile on the floor at a distance of 20 cm.

What material to choose for seam decoration

The easiest way to join is to carefully trim and fill the seam with sealant. However, even a straight-line joint is difficult to cut perfectly on a material such as tile.

Therefore, the connection of tiles and linoleum is best done with a special decor, the edge of which slightly goes over the material, hiding the place of cutting:

Conclusion: the choice of the connecting element is done based on the length of the joint, its shape, the difference in height of the floor planes. The color of the connection should be selected in accordance with the design of the entire room - contrasting or in tone with the coating. Interior photos with zoning will help everyone choose to their liking.

Joining tiles and linoleum

The easiest way to connect the junction of tiles and linoleum when they are on the same level. However, if the decorative finish is mounted on the finished rough coating, then differences in the height of the planes cannot be avoided: the tiled surface will be higher than linoleum, especially if the “warm floor” system is mounted under it.

To level the difference, after laying the tiles, the rest of the floor can be raised with a leveler - a mixture that forms a smooth and durable surface (self-leveling floor). To continue the work, you will have to wait until the screed dries well. A faster and less dirty method is laying plywood sheets or soundproofing substrates that can level surfaces with a slight difference in height.

Docking aluminum sill

The lids are cut to the desired length (grinder or hacksaw for metal), screwed with screws. For concrete substrates, marks are first made at the attachment points, then holes are drilled under the plastic tips of the dowels.

There are models with a secret method of fastening: screws are fixed with hats in a special nut groove on the underside, and then the nails are hammered into the prepared holes in the floor. Such a threshold between the tile and linoleum forms a tight, smooth fit, in which debris does not accumulate (read also: "How to make a threshold between a laminate and a laminate - methods").

Joint design with a flexible profile

Flexible profiles can be metal or PVC. The plastic profile consists of two parts - mounting and decorative.

The profile of the PVC joint between the flooring is made out as follows:

- Cut the profile to the desired length.

- Attach the bottom with screws or glue along the seam.

- The decorative part is heated in warm water.

- Lay on the mounting profile and snap.

It is necessary to decide on the material for the design of the seam before starting work on finishing the floor, since it is more convenient to connect the tile with linoleum with a flexible metal profile at the stage of laying ceramics.

Procedure for docking with a metal profile:

- Mark the interface.

- Give the profile the desired shape.

- Lay the tile, cutting in accordance with the intended line of the joint.

- The profile is laid simultaneously with the tile, inserting its edge into the groove of the profile.

General Provisions

Linoleum today is one of the most popular types of flooring.

To prove this, it will be enough to mention the main advantages of this material:

- Low cost. There is some difference in pricing policy depending on the class of material, since household models are less wear resistant and have a more diverse appearance, and commercial, but much more durable:

| Linoleum class | Approximate price per square meter |

| Domestic | From 200 rubles |

| Commercial | From 450 rubles |

- Wide range of available colors and patterns. You can probably pick up something suitable for the interior of your home,

Showcases with household linoleum

- Easy care. Normal wet cleaning will keep the linoleum coating clean. If suddenly a more expressive stain appears on it, then it can be eliminated with the help of any household chemicals,

Caring for linoleum is easy

- DIY styling. Everyone can even cut and lay linoleum canvases even without special instructions, but we will talk more about how to properly dock them.

Laying linoleum in the living room

Thus, it becomes absolutely clear why linoleum is in such high demand as flooring. Now let's move on to the most important thing:

Docking options linoleum paintings and their competent implementation

There are several methods for joining the edges of linoleum paintings, and not all of them will satisfy the perfectionist. But still, I will introduce you to everyone so that you are aware of not only how to do it, but also how not to do it.

Good day! than to join the tiles and linoleum, but fastening the threshold for self-tapping screws is not suitable, a warm water floor is laid

Tatyana, now manufacturers began to produce self-adhesive thresholds. They are not fastened with screws, but simply glued. For example, you can use the Rico Floor Board self-adhesive threshold. It is a polyvinyl chloride strip with elastic, soft edges. Mounting such a threshold is very simple:

We floor with linoleum. Do not take into account doorways. Now we are thinking how to fill a void of 10 cm ?! Are there such wide alum.planks? Thanks.

Natalya, no - there are no aluminum or plastic sills with a width of 10 centimeters. Are you really left with 10 cm linoleum scraps? If you don’t stay, then buy at least 1 linear meter of such linoleum.

Hello. It is required to issue a joint of porcelain tile with linoleum in the doorway. but you can’t drill the floor, there is heating. The level difference is 9 mm.

Igor, your problem is very easily solved.

You will need to purchase an invoice joint overlapping threshold. They are plastic self-adhesive strips.

The inner part of the nut is made in such a way as to level out small different level differences between different types of floor coverings (from 0 to 1 centimeter).

The durability of the product is guaranteed by its increased resistance to abrasive loads and the action of aggressive chemically detergents.

A similar sill differs from its analogues in that it is very simple to install. It will be enough to measure the desired length of the strip, saw it off and glue it using the adhesive layer already applied to it. Powders are varied in color and texture. Therefore, you can always choose sills for any design.