A variety of materials are used to fence the site in a summer co-op or in a suburban village. The main criterion for their choice is safety and maximum access to sunlight so that beautiful flowers and shrubs can be planted along the perimeter along the perimeter.

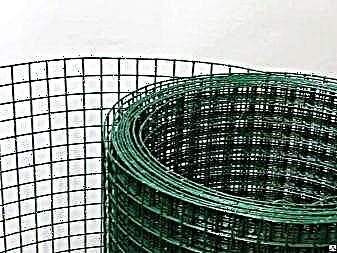

Until recently, netting was widely used for this type of work, but its appearance has lost its relevance in the modern design of the fence. A worthy alternative was the welded mesh.

Watch the video how to install a fence from a grid

Between themselves, the rods are connected by contact welding, which represents a high degree of fastening. The pins located vertically are additionally equipped with stiffening ribs. When choosing a material for the fence, the mesh must be immediately equipped with fasteners and supports.

Benefits of Welded Mesh Fence

• unhindered penetration of sunlight and air, which provides favorable conditions for plant growth,

• low weight of the structure, which means that you do not need to build a solid foundation,

• high resistance to any weather conditions (with large winds, no windage is created, which loosens the supports),

• the surface is absolutely safe, there are no sharp protrusions and corners,

• affordable installation of the structure, any owner who does not have a construction specialty can handle it,

• if necessary, the damaged fragment can be replaced with a new section,

• maintenance does not require annual painting, additional corrosion treatment,

• the coating prevents the formation of rust on the surface,

• aesthetics in a classic style.

The drawbacks of the welded mesh fence include only the visibility of the territory. In the summer, this flaw is easy to fix by planting green spaces around the perimeter to create a hedge.

Rules for choosing a fence depending on the purpose

• It is recommended to use a grid with the following parameters to equip the fence in a private home or at a summer house: rod thickness from 4 to 4.5 mm at a height of 1.23 to 2.03 m.

• Industrial areas may be fenced with nets having a rod thickness of 4.5-5.5 mm at a height of 2.03-2.24 m.

• Playgrounds and the territory of various institutions are drawn up by a fence made of welded wire mesh with the following parameters: rod thickness from 4 to 5.5 mm with a height of 1.23 to 2.24 m.

To prevent penetration through the upper part of the sections, it is recommended to install L-shaped tips. In addition, barbed wire can be pulled.

Welded wire mesh installation

Before installing the fence, check the equipment. Among the main elements should be available:

• sections (standard width 2.5 m),

• supports (square or round) with holes for fastenings and plugs,

• fasteners (staples, clamps, etc.).

If a wicket or sliding door system is planned, the kit is supplemented with the necessary mechanism.

There are several ways to install a welded wire mesh fence.

1. The driving method involves the use of a round form of support, which, under mechanical action, is buried in the ground per meter. It is carried out using screw piles. This option provides for a preliminary study of the soil.

2. Installation of supports on a columnar foundation is carried out using anchor bolts. Before mounting, flanges should be welded to the lower parts of the supports.

3. If the groundwater level is high, you can install supports in the pits, covered with crushed stone. To achieve stability, sand is added and each layer is densely tamped.

4. The combined method involves digging holes under the supports, 1 m deep. Half of the depth is concreted, the rest is sprinkled with solid soil or gravel.

5. On sandy soils, experts recommend using the full concreting method. Sand and gravel are added to the excavated pits alternately (10-15 cm each) and densely compacted. Next, the support is installed and poured with concrete. Pre-made formwork for a pipe or strut will help maintain verticality.

DIY installation steps for a welded wire mesh fence

• Clear the installation area of the fence, level the ground.

• Mark the locations of the supports. Dig holes 1 m deep.

• Make a sand bed of 10 cm and compact it with a rammer. Next is the filling of crushed stone (10-15 cm) followed by tamping.

• Install 50 cm of asbestos pipe cuts in the center of the pits. The diameter is more suitable 150 mm. Around the pipe, add crushed stone by ramming it carefully. The layer thickness should not exceed 30 cm.

• Install a support in the center of the asbestos pipe and pour it with concrete to the edges of the asbestos pipe. It is important to temporarily fix the carrier to maintain verticality, or to provide spacers. When all the pillars are strengthened, you need to give time for the concrete to harden.

• Pour the rest of the pits with rubble, ramming each layer tightly.

• Pour the rest of the pits with rubble, ramming each layer tightly.

• Further work should be done after the concrete base has completely solidified.

• Using fasteners, grid sections are installed in turn. The top of the supports should be closed with a plug to prevent moisture from getting inside.

• If necessary, fasten the L-shaped lugs to the top of the guard.

High-quality installation will save unpleasant surprises during the operation of the fence. And maintenance will consist only in periodic cleaning of the net from weeds and dust.

Features

Galvanized welded wire mesh is designed for areas where strength is paramount

Previously, for fences of this design, the "Chain-link" grid was used. Given that the metal wire from which it was made is amenable to corrosion and short-lived, it was first used as temporary fencing. However, over time, the technology of manufacturing a durable mesh was mastered. Mechanical stability was achieved by the fact that the mesh began to be used not welded, but welded. The source material is galvanized wire.

The mesh elements are spot welded, providing a rigid overall profile of the mesh web. Thus, welded wire mesh fences today are a solid, durable fence.

Application area

Fences made of welded galvanized wire mesh are widely used for fencing both private areas and territories of various institutions.

In everyday life, fences made of metal mesh can be used in the following cases:

- To limit the location of estates, suburban summer cottages, as well as various personal territories.

- To provide reliable protection against predators of poultry accommodation sites. Small sections with small cell sizes can be used to make cages for rabbits.

- Fencing of individual beds or greenhouses.

- Creation of decorative fencing of front gardens.

In public places and at enterprises, mesh fences are installed to:

- Protections of sports grounds.

- Restrictions on access by unauthorized persons to high-security facilities: railway stations, gas and electric substations, gas stations. For such purposes, the wire diameter is selected slightly larger than usual. Sectional fence designs for such objects must satisfy safety requirements: have high reliability and appropriate height.

- Enclosures for school grounds, park areas, open utility areas of supermarkets.

- Production of hedges in nature reserves and forest areas. With the help of such fences, the inhabitants of forest or steppe zones remain in the areas allotted to them.

- Protections of public and cooperative parking of vehicles.

- Fencing of pastures and corrals for animals in various farms.

Advantages and disadvantages

The following advantages are inherent to fences or galvanized fences from a welded mesh:

Welded galvanized mesh is very popular due to its high performance properties and a variety of applications

The fenced area is well ventilated and the fence does not restrain the sun's rays. This has a positive effect on plants, since the greenhouse effect is not created on the beds.

Along with positive qualities, such a hedge has a very serious drawback. Due to its excessive visibility, mesh fencing is not always used as a street fence.

Classification

Depending on the material used to protect the metal from corrosion, the nets are divided into the following types:

- Not galvanized. This is a mesh made of metal without any protection against corrosion. In order for it to last as long as possible, it must be painted after installation. In the future, painting should be regular.

- Galvanized. The metal of such a grid is protected from corrosion by a thin layer of zinc. It is resistant to atmospheric precipitation.

- Polymer coated. The mesh has additional corrosion protection. This is achieved by applying powder to a metal base, which is baked in special ovens. With this technology, a protective polymer layer is formed.

- With double protection. Such nets are coated with a thin layer of zinc, and then with a polymer mass.

- Stainless steel mesh.

By design, fences are divided into two types: tension and sectional.

The stretch fence consists of freestanding supports and a roll net, which is stretched between them.

Sectional fences are mounted from prefabricated structural elements, one of which is a section. In accordance with the selected material, they can be delivered with various types of corrosion protection, including the polymer coating of the sectional fence. Then these sections are assembled together in one design, which in its final form is a sectional fence.

Installation technology

Installing a welded wire mesh fence can be done easily with your own hands. But first, it is necessary to carry out preparatory work: to acquire the necessary materials and parts, as well as to prepare the tool and accessories.

The choice of materials and the necessary tool depends on the type of fence: tension or sectional.

A sample list of materials is as follows:

- for tension fences - roll mesh,

- for sectional fences - finished sections,

- for tension and sectional fences - poles, embedded parts, concrete or cement mix.

Tools and fixtures: welding machine, screwdriver (for sectional fences), marking tool (tape measure, level or plumb), shovel (shovel and bayonet), yamobur, container for solution preparation.

The construction of the fence is recommended in the following sequence.

Modern Welded Fences

The basis of any modern welded type fences is a reliable mesh made of steel and high-strength wire with a thickness of 4-5 mm. By means of high-quality spot welding, reliable frame bonding is performed at the points of wire intersection.

The cells can be rectangular, square, trapezoidal and diamond-shaped. The galvanizing process is sometimes carried out immediately after welding, but most often a high-quality galvanized wire is already in use.

Types of Welded Fences

State standards provide for the production of several main types of welded fences:

- With classic non-galvanized metal mesh. The most budget option, favorably with a variety of formats, different in terms of thickness guides and cell sizes.

- With galvanized metal mesh, well protected from corrosion changes and damage. A high-quality product of this kind is able to last almost a quarter of a century without problems.

- With a metal mesh in a polymer shell. It is the most modern look, and has not only an attractive appearance, but also extreme resistance to corrosion changes.

It is the latter version of the rolled welded mesh that is most often used when installing fences.

The purpose and use of the fence or fencing from the welded mesh have a significant impact on the construction method:

- The tension type fence favorably differs in very easy and simple installation, therefore it is most often used to protect summer cottages and garden plots, as well as the adjacent territory from unauthorized entry. Among other things, just such an option is in demand as a temporary design.

- A sectional type fence is a more expensive and reliable option, which involves fixing the welded mesh to a metal base made on the basis of a profile pipe. It is characterized by high reliability, as well as simple and convenient self-assembly.

Polymer coated welded wire mesh

A sectional fence based on a welded mesh with the application of a durable polyvinyl chloride coating is very durable. Such a polymer is applied by immersion of the mesh in a special solution or by powder coating inside a heating cabinet.

Materials

All materials used in high-quality modern fences based on welded metal mesh are characterized by the following advantages:

- increased resistance to corrosion changes,

- maximum simplicity and ease of self-assembly,

- durability and practicality of operation,

- a wide selection of colors and cell sizes,

- undemanding care,

- hassle-free service.

Thanks to the unhindered penetration of the rays of the sun and air, it is possible to provide optimal conditions for horticultural and flowering crops. The low weight of all materials avoids the construction of a solid foundation. In addition, the complete absence of sharp protrusions and corners and material makes the operation of such structures absolutely safe.

The tangible disadvantages of materials and construction include only significant visibility of the entire enclosed area. If in summer there is the possibility of planting around the perimeter of various green spaces, then in winter such a decision will not take its due effect.

Polycarbonate fencing has appeared relatively recently.A polycarbonate fence is a durable and aesthetic option for protecting a house territory.

You can see design options for decorative fences made of wood here.

Design

The right choice of material not only provides ease of maintenance, but also allows you to get a very aesthetic design of the fence in the classical style. In addition to the “flat” format, manufacturers produce a very attractive “3D mesh”, which has special profile bends.

3 d metal sectional fencing

Depending on the general concept of landscape design, a welded galvanized or polymer coated mesh can be installed using a strip foundation, brick supports or pillars based on a steel profile.

Perimeter marking

First, you should mark the line of the territorial perimeter. This is done with wooden stakes and a rope stretched between them. Next, the mounting points of the poles are determined. Marking is best done with a tape measure. If a sectional fence is being constructed, the distance between the installed poles must be increased by 15-20 cm. The reserve is necessary in order to use special section fasteners. The depths of the posts are marked with wooden stakes.

Mounting the support posts

To facilitate the alignment of the pillars in height, the bottom of the pit is covered with sand, gravel or small gravel

The strength of the fence depends on the quality of the supports; pipe supports are considered the best. Support poles can be reinforced concrete or wooden. The cross section of a column for mesh products with a rod thickness of 4 mm or more may be 60 * 60 mm.

Before installing the pillars, you first need to dig foundation pits, holes or holes in the ground. In this case, the depth of freezing of the soil is taken into account.

After that, a support post is installed in each hole. Using a plumb line or level, she is given a vertical position in which she is fixed with spacers.

Then a cement mortar is prepared, consisting of 3 parts of sand and 1 part of cement, with which the foundations are poured under each column.

After installing the pillars, you can proceed with the installation of the mesh web.

Fastening the fence

If a roll mesh is used, then it unfolds, then its beginning is attached to the clamp or bracket on the post. After it is pulled in a support span and fixed in the same way on the next column. Thus, the mesh is stretched in each span.

When mounting a sectional fence, the sections in the span can be fastened by welding or self-tapping screws.

How to choose

The following criteria influence the correct selection of welded mesh fences:

- Product durability. Rigidity depends on the diameter of the wire from which the mesh fabric is made, as well as on the size of the cells. The larger the diameter of the rod, and the smaller the cell, the stronger the fence.

- Overall dimensions of the mesh base. This applies, first of all, to tension fences, since a roll mesh is used for them.

- The quality of the rods. They should be smooth, without bending or deformation.

- The shape and size of the cells should be the same on the entire mesh web.

- The protective layer must not be damaged.

- The place of welding should be without flaws.

In addition, the price of the canvas is of no small importance.

Varieties

A metal mesh for fencing is made of wire of various thicknesses at the points of its interweaving. The grid differs in the following ways:

- To size and the shape of the cells: options come in the form of a regular rectangle or rhombus, and non-standard trapezoid and other intricate shapes.

- By structure Distinguish a grid of 2D and 3D. The first view is flat, has no bends and corners; the cells are usually of regular rectangular or square shape. At the factory, the product is painted green, but at the request of the customer it can be repainted. The 3D mesh is stiffer due to bends. There can be 2 or more bends; they can be used as cable channels for wires.

- By type of coverage distinguish uncoated galvanized and polymer coated mesh:

- The uncoated variety is the most affordable. Its disadvantage is that it requires additional anti-corrosion preparation. Typically, preparatory work consists in painting, and in the future, the paint must be periodically updated.

- The second type is galvanized wire mesh. There are galvanic and hot methods of applying a layer of zinc. In the first case, the zinc layer is applied using various primers. The layer is not very strong, over time it can be damaged, which will lead to corrosion. In the second case, the layer is more durable, however, the price of such a mesh is much higher.

- PVC coating is the finish. It is applied after a layer of zinc. The result is a product that can withstand significant temperature changes and other climatic phenomena. The smaller the mesh size, the stronger the mesh.

Due to the high cost, this variety is rarely used for the manufacture of conventional barriers.

- By packing method. Welded mesh is usually supplied to consumers in rolls or cards. Sizes of rolls can vary in weight (from 50 kg to 0.5 tons) and in length (15-30 m). The diameter of the rolled wire is relatively small, so this mesh can be easily rolled up. This gives the net some transport advantages. During installation, it is easily straightened and takes the desired shape. The strength of such a product is slightly higher than that of the Rabits grid. The cards are rectangular sheets with a size of 1.5x2 m, made of especially durable wire, which cannot be bent and rolled up.

Design

Depending on the design, mesh fences are usually divided into two types:

- Sectional mesh fence. It is often called European. The name "sectional" speaks for itself. Such a fence is a finished panel. They are supplied with mounting hardware, with which the fence is assembled in a short time, like a designer. Due to their attractive appearance, such fences are often installed in parks and squares, near office buildings and similar places.

- Tension welded fence. In this case, the tape method, roll mesh are used. Installation is more time-consuming and requires an assistant. To support the tension fence, you can use concrete, wooden or metal poles. Concrete bearings are considered the most reliable option, since they are more durable than wooden ones and do not corrode like metal ones. If we are talking about a summer cottage, then the pillars can be made independently. For more respectable places, manufacturers offer ready-made supports with hooks and other necessary accessories.

As for the distance between the supports, experts advise choosing an installation step of 2.5 m.

Useful Tips

In order for the fence to be durable and reliably protect the property from unauthorized intrusion, you need to know some rules to be followed when choosing:

- Strength. Depending on the thickness of the metal rods from which the welded mesh is made, as well as on the internal size of the cells, its strength also changes. The thicker the rods and the smaller the cells, the more durable the product is considered.

- The size of the mesh web. This applies primarily to the roll net. Dimension should be selected depending on what height the fence is needed. Manufacturers offer various options: 0.5 m, 1.7 m, 2 m and others.

- Cut or bend quality. The rods should be smooth, without flaws. This will affect the life of the product.

- The shape and size of the cells, as well as the cross section of the wire must be identical to those stated in the documentation.

- The quality of the protective layer is also of great importance. The durability of the fence depends on its integrity.

- If the technology has been followed, the welding will not damage the wire, and the welding spot will be strong and reliable. If you purchase a roll net, you can check its strength by unwinding the roll a bit. If welding does not crack, it means that you have a high-quality product.

- A certificate of conformity or other documentation confirming the quality is required. One technical passport is not enough.

- All parts and accessories must be equipped with high-quality, and their quantity must comply with what is stated in the instructions.

Welded wire mesh fences

Such hedges are installed with the help of special racks, between which the welded mesh produced in rolls is stretched. A characteristic feature of the roll net is the relatively small diameter of the wire, which allows you to twist the product into a roll.

This type is convenient in transportation and is able to straighten before use with ease. As for operational data, the product has poor mechanical characteristics. These fences are the simplest and most affordable option that can be used both for private and industrial purposes.

Welded mesh sectional fences

Installation of this design is the most expensive than simple stretch work, but at the same time, sectional systems made of welded mesh are among the most popular options.

Components for such fences are available in cards or gitters, which are welded sections having certain commensurate dimensions, length and width. Such fencing is made from thick rods and cannot be rolled up.

Examples

Metal fences are diverse. According to the main criteria, welded wire fences are no worse than stone or brick fences. The production uses high-quality steel alloys, providing a high level of reliability, strength and durability. You need to choose them, given the functions and principles of the design of the site, focusing on products from well-known manufacturers.

Belgian company products are popular on the world market "Bekaert", which has been supplying quality systems of welded wire fencing for a long period. Domestic manufacturers offer products at a lower price, but Bekaert remains in perfect quality, reliability and durability.

Russian TM "Cascade" specializes in the production of materials for this type of fencing. The galvanized rolled mesh of domestic production allows you to build fences at industrial enterprises, in summer cottages, on the banks of water bodies.

The choice of fencing from a welded mesh is the right solution, providing multifunctionality, namely, reliable protection while maintaining the option of viewing and penetration of sunlight over the entire territory of the fenced area.

Currently, such fences are very popular mainly in the West, but have already begun to spread rapidly in the CIS.

For tips on installing a welded wire mesh fence, see below.