Recently, in construction, to perform household tasks and when creating various crafts, a hot glue gun has become popular. This is a special electric tool that allows you to quickly connect different materials.

It is charged with cylindrical glue sticks that contain polyurethane glue. We will figure out how to use a glue gun so that all actions are not only effective, but also safe.

How to use a thermal gun

The design of the glue gun is not so complicated and it is also unpretentious in use. But, as with any other tool, you need a little practice to get used to it for effective use.

Do not try to tackle difficult work or crafts the first time, take any unnecessary material, scraps, pieces of plastic or wood and try to practice them. Glue different materials together and check the result, note the time of glue hardening.

The order of application looks like this:

- First, take care of the workplace. The surface must be protected from glue, for which they put a silicone mat or cardboard sheet on it. So that the hair does not interfere, they are removed, and protective gloves are put on the hands. Children and pets are best protected from the place of work. It is good if the room is well ventilated.

- We install the gun in an inclined position, resting it on a special stand with the nose down. Please note that the nozzle is directed towards a protected area, as a little glue (no more than 7 mm) may leak out during heating.

- We connect the thermogun to the network and press the power button, if any. If there is no button on the case, then the heating process will begin immediately upon connection.

- Filling the glue gun manually is simple - an opening for glue sticks is provided from the end of the tool. "Cartridge" is installed smoothly, until it stops. Do not insert foreign objects into the hole. Only glue of the appropriate diameter is suitable. Hot melt adhesive cannot be reused.

- Depending on the manufacturer of the thermal gun, the tool will need 3 to 5 minutes to heat up. At this time, you do not have to press the trigger strongly, because of which the device may fail.

- If the thermal gun supports temperature control, then set the desired one. The recommended range is from 170 to 200 degrees Celsius. If you set the temperature lower, then the tool will need more time to melt the hot melt in the chamber. High will lead to a boil of glue, because of which "threads" will appear.

- Some models of thermoguns are equipped with a trigger control, allowing you to set the amount of glue supplied. To do this, tighten the screw.

- To start dispensing glue, just gently pull the trigger. The supplied volume of the molten adhesive mass depends on the pressing force.

- The parts to be glued should be cleaned, degreased and dried. By applying glue, the surfaces are tightly connected to each other, pressing them with a dense fabric. It must be understood that the adhesive mass at this stage is still very hot, so we do everything carefully.

- If the glue stopped coming out of the nozzle, it means that the rod is over. A new portion is inserted into the hole at the end. While pulling the trigger, hold the rod so that it is in the feed mechanism.

- After completing the work, disconnect the tool from the network. Next, put it in an inclined position and leave it for 10 minutes to let it cool. Remains of glue may leak out of the nozzle at this time, so be careful.

- After the tool has cooled down, it is allowed to store it in any positions. It is advisable that the place is protected from dust and debris.

During bonding of parts, thin threads similar to a web will form. They are easy to remove after solidification. If the working surface allows, then you can use a vacuum cleaner (with a nozzle in the form of a small brush for cleaning clothes).

What materials can be glued

The glue gun is widely used, which is explained by the versatility of the polyurethane from which the glue sticks consist. The adhesive composition begins to melt at a temperature of +105 degrees Celsius and is suitable for bonding any materials that can withstand such heating.

Separately, we highlight the features of high-temperature polyurethane rods, the melting point of which is +150 degrees. They are used if the workpiece will subsequently experience elevated temperatures, for example, located near a heater or battery.

Polyurethane adhesive is suitable for joining the following materials:

- textile. Leather, silk, linen, cotton and others. The exception is synthetics that are susceptible to high temperatures,

- tree. Almost any wood is suitable, even wood waste,

- rubber,

- bung,

- plastic. You can work with polymers: polyethylene (with and without reinforcement), polypropylene and so on,

- ceramics,

- faience,

- glass,

- metal,

- paper,

- cardboard,

- a rock. Both artificial and natural.

Each material has its own characteristics that must be considered. For example, when working with metal parts, the bonding site will have to be additionally heated with a hairdryer, otherwise the glue will not stick to a cold surface. This is explained by the high thermal conductivity of the base, because of which the applied glue immediately polymerizes.

There are subtleties in the processing of ceramics - the glued area is treated with sandpaper, which will remove the top layer of glaze, and then cleaned of dust.

Features of the choice of glue sticks

Glue sticks come in several colors. From what color the rod depends on what material it is suitable for:

- transparent - universal, suitable for any materials,

- white opaque - glass and metal,

- yellow transparent - wood, cardboard, paper,

- black or gray - used as a sealant and insulation, they have a high melting point.

An exception is decorative glue sticks of different colors and textures. They are universal and the color they have is exclusively decorative in nature - to make the craft beautiful or to choose the color of the glue to match the color of the parts to be glued.

Subtleties of work

As an example, consider how to glue linoleum with a thermal gun. This flooring material is popular due to its accessibility, practicality and abrasion resistance. But, laying it, it is necessary to achieve high-quality tightness and invisibility of the joints, which can not be done with conventional glue. Here, for gluing joints, a glue gun is useful.

Bonding the floor with a hot glue gun

Bonding the floor with a hot glue gun

The work is carried out as follows:

- Cut to the base of the edge of the material.

- We clean linoleum from dust and pollution.

- We fill the gun with adhesive.

- We connect the tool to the network and fill the joints with hot glue mass.

- We remove the excess glue until it is frozen.

Kleepistol also finds other uses in everyday life, due to its valuable quality - the glue quickly seizes. To dry, it takes about 3 minutes, when it takes hours for liquid nails and sealants.

Hot glue is suitable for connecting engineering communications. It also acts as a good sealant, where the seams completely harden within 10 - 15 minutes. To dismantle the structure will have to re-heat the glue. The compound gets a solid structure that does not change over the years. The thermogun is also popular for outdoor applications, since the mass used will not deteriorate under the influence of the sun, frost or precipitation.

Hot-melt adhesive can firmly fix the baseboard or door platband. But, if you need to connect the ends of a long polyurethane molding, it will not be the best choice. The fact is that if you slightly change the parameter of humidity and temperature of the molding, its structure changes - it shrinks, which can lead to delamination of the glue. Therefore, it is important not only to be able to use the glue gun, but also to know for which structures it is suitable.

Bonding the baseboard with a glue gun

Bonding the baseboard with a glue gun

The tool is also popular in the furniture industry. Using hot glue, fabric and decor are fixed, decoration elements are fastened, and much more. You can even glue shoes with a heat gun.

What materials cannot be glued

Some combinations of parts cannot be fastened together. Polyurethane with silicone, concrete, cement, plaster and putty is poorly glued. Add glossy paper to this list. It is important that there is good adhesion between the fastened parts.

Thermoplastic adhesive is not recommended to fasten objects located near the fire and exposed to high temperature - it simply melts (at from +105 degrees Celsius).

How to clean a glue gun

Expensive, high-quality thermoguns, of course, last longer. But, if you neglect the rules of operation, then even an expensive tool can quickly fail. Use glue from a proven and common manufacturer, after each use, clean the nozzle from its excess.

It makes no sense to clean the inside of the nozzle from the adhesive mass. It is made of metal, in addition, it heats up, so the glue there solidifies tightly. It will drain itself when reusing the tool.

It happens that hot glue gets on the body of the gun, where it freezes. To remove it, a piece of foil is placed in this place and touched with a heated soldering iron. As a result, the adhesive mass will melt and stick to the foil. Most often this situation happens if you use low-quality rods. To remove residual mass from the tool, you can also wet a napkin with ethanol and “walk” through the body and nozzle. To clean the area near the tip, a regular toothpick is suitable. If you do not have ethyl alcohol at hand, use acetone.

Common faults and solutions

Any tool, sooner or later, will begin to junk, so it will not be superfluous to know about the most frequent breakdowns of the glue gun. Consider the main cases and methods for solving them.

Spoiled rubber coupling

This element is located at the entrance to the heat chamber and prevents molten glue from entering the tool. The coupling can simply break after the expiration date (frequent on-off cycles) or in case of an unsuccessful attempt to extend the rod.

If heated hot melt glue enters the body of the glue gun, this can damage the insulation, which will lead to a short circuit. If physical wear has happened, then there's nothing to be done. But pulling the rod is not recommended. If you need to replace it, just cut the old one and insert a new one. The glue remaining inside will come out when heated.

What can be glued

The principle of operation of the glue gun is that the rods with the adhesive melt under the influence of temperature, and hot glue can be applied pointwise or evenly. The curing process begins in 1-15 minutes, depending on the thickness of the coating. Glue guns are used by needlewomen, radio technicians, engineers, builders and home craftsmen for domestic purposes. Due to its good adhesive properties, hot glue gun can connect fragments and surfaces of different structure:

- Small wooden structures.

- Glass elements, mosaic, beads.

- Flaps of fabrics, leather material.

- Metal and rubber products.

- Items made of plastic, PVC panels.

- Ceramic fragments, foam.

- Paper and cardboard products.

Glue gun is used in various fields. The resulting seams have high elasticity and strength. Tests show that even metal objects can be glued to concrete and plastered surfaces. It is allowed to use hot melt adhesive as a sealant, since it does not allow moisture to pass through.

Important: The melting point of the gun glue exceeds 105 degrees, so it is not recommended to apply the composition to heated surfaces and to glue objects located in the immediate vicinity of the fire source.

How to choose a thermal gun

A wide selection of models of glue guns from different manufacturing companies opens up before customers. To choose the right tool, you need to consider how often you will need to use hot glue. If a glue gun is needed for one-time housework, it is not necessary to purchase an expensive and powerful product. Needlewomen use professional tools, since different surfaces and elements need to be glued together often. When choosing an adhesive gun, consider:

- Power. For single use, a model with a power of 20-100 W is suitable, for permanent use - a gun at 300 W and above.

- Automatic adjustment. Simplifies the bonding process, the device independently selects the melting power of the rods.

- Performance. Hot glue is obtained at a melt speed of 5-30 g per minute. For bulky work you need a powerful glue gun.

- The temperature of the melt. Take into account the materials with which to work: cardboard, textiles - 105 °, wood, glass, metal - 165-170 °.

- Power supply. The gun for applying glue for domestic use works from the network, there are professional devices on batteries.

If you have to carry out a large amount of work, you need a gun with a high melt rate (gluing plywood, PVC overall products). Since the glue hardens very quickly, you need to have time to apply it to the surface and firmly press the fragments. For point bonding of small elements (glass, beads, beads, rhinestones), a gun of minimum power and productivity is suitable if the work is performed one-time. Professionals who often need to glue a wide variety of fragments, it is advisable to choose a more expensive semi-automatic type device (10-15 minutes without a network) or a battery model - 45-120 minutes of uninterrupted operation.

Note: It is worth paying attention to the presence of additional options that a thermal gun can perform. These include the ability to adjust the temperature when working with various materials - heating, melt range, standby mode. The readiness of the device for operation is indicated by an LED indicator. Some models are equipped with a backlight and a viewing window to control the charge of the adhesive rods. Some are equipped with docking stations with additional capacity. It warms up the glue and prevents molten droplets from reaching the work surface.

On the video: How to choose a glue gun?

Functional and design features

The use of guns for hot glue is gaining more and more popularity, as the resulting compounds reliably fix the elements to be glued and dry out very quickly. Using rods, you can connect homogeneous and heterogeneous materials, the strength of fixation is similar to metal fasteners. Functional features of thermoguns:

- High speed polymerization of liquid pistol glue.

- Reliable connection of products, filling voids, cracks.

- No traces of adhesive after separation.

- When heated, the composition does not emit / does not evaporate toxic substances.

- Consumables are inexpensive, the rods are economically consumed.

A handicraft gun is suitable for children's creativity, but it is advisable to carry out work under the supervision of parents. Hot glue may leave a burn on skin contact.

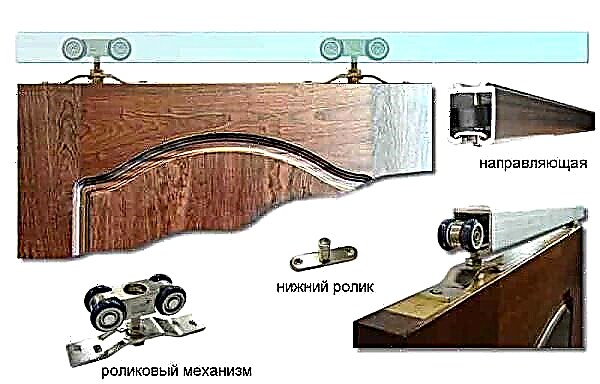

The design of the guns may vary depending on the model and manufacturer, but the following parts are the basis of the device:

- Housing made of high quality plastic. It does not allow the device to overheat and makes the tool lighter, which is very important for work. The best option is a gun weighing 300 g.

- A heating chamber with one or more heating elements. The thickness of the rods, which are suitable for a particular tool, depends on the dimensions of the heating unit.

- Guide sleeve made of heat-resistant rubber. One side of the clutch is connected to the heating chamber, and in the second part the glue stick is fixed.

- Feed unit - trigger with pusher rods. Triggers are sliders and swivels. The wear resistance of the feed unit depends on the smoothness of the pair with the pusher.

- The nozzle of an electric gun made of metal alloy with a heat-insulating layer (called nozzle, nozzle) serves for dosed supply of glue, is equipped with a shut-off valve.

The handle of the device can be equipped with anti-slip pads. Some models are equipped with a drop protection function - a special ball prevents glue from leaking out during interruption of work. When choosing a tool, you need to check the smoothness of the trigger, since the feed unit is the most vulnerable. Each thermogun uses rods of a certain diameter, the size depends on the dimensions of the coupling.

How to use

There are no particular difficulties when working with a glue gun. First you need to charge the polyurethane rod into the device. It is installed on the back of the instrument. Principle of operation: the rod is pushed into the heating zone, and after melting, the adhesive dosed flows out through the nozzle. How to use a glue gun:

- Install the adhesive core of the required diameter.

- Connect the device to the network and leave for 5-10 minutes.

- Check glue heating - a drop should appear.

- Apply glue to the desired location pointwise or with sutures.

- After a certain time, turn off the gun.

After the device cools down, you can resume work. Hot glue on the edge of the nozzle forms a dense film. It must be carefully removed before reusing the tool. The time it takes to heat up the adhesive depends on the specific model of the thermal gun and the diameter of the rods.

Note: If one heating element of low power is installed in the device, the glue will be heated to 105 degrees. Therefore, you need to work faster until the composition has hardened.

Terms of Use

A glue thermal gun can glue a variety of fragments. It is used in creativity, needlework, construction and for domestic purposes. It must be borne in mind that it is necessary to work with the heated substance - hot glue should be used carefully, excluding skin contact. Basic rules for the operation of pistols:

- Charge only rods of a suitable diameter into the coupling, otherwise glue will not be pushed to the heating unit.

- In order for hot glue to flow evenly, the nozzle of the gun must be cleaned after using the device.

- The tool is equipped with a plastic case that does not overheat - gloves are optional.

- A special stand is included with the device. It is necessary to install a gun on it during pauses in work.

- Do not touch the glue flowing out of the nozzle with your hands, so as not to burn yourself and do not need to put the heated device on its side.

Consumables are inserted into the receiver without effort, the trigger is pulled gently, since it is the weakest feed unit of the device. The device must not be allowed to overheat; during operation, short breaks should be made so that the heating elements have time to cool. Within five minutes, the polymer core acquires adhesive characteristics and is ready for use.

Use in construction

Thermal guns can be used not only for creativity and needlework. Devices help to quickly solve everyday problems, you can use guns in construction and repair work. What is glued with hot glue in construction:

- Close up of gaps in window frames.

- Sealing the seam between the tiles.

- Bonding of wooden structures.

- Filling plumbing connections.

- Sealing cracks in the doors.

With molten glue, you can fix the fallen tile, stick the curb tape to the bathtub, seal small gaps and seams. Hot glue sticks metal, adheres well to tiles, ceramics, glass, wood, plastic, but it is not recommended to close cracks in concrete substrates - the strength of the composition will be much lower.

Application for creating decorative products

Handicrafts, samples of creativity, hand-made works are now in great demand. Some needlewomen create exclusive things for sale, make beautiful souvenirs, original art compositions. In working with a large number of small elements, a thermal device with glue is an indispensable thing. What can be glued with glue gun rods:

- Natural and artificial fabrics.

- Decorative pearls and rhinestones.

- Corrugated cardboard, colored paper.

- Flowers made of polymer clay and foamiran.

- Finishing accessories, buttons, beads.

The needlewoman will be able to use the hot glue of the gun to create exclusive jewelry, with its help it is convenient to make grid frames for dishes, to make intricate patterns and compositions. To glue does not stand out on a decorative background, dyes are added to it. It is allowed to combine materials of different structure.

Thanks to the dosed feed, the consumption of the rods is much more economical than the use of PVA, silicate or construction glue. Pistols are convenient to use for repairing shoes (the buckle has come off, the bow on the shoes has come unstuck), used in the assembly of radio parts, and fix microcircuits to glue.

What you need to know about glue sticks

Polymer rods / stickers (the so-called adhesive for thermoguns) are not the same. They differ in length, diameter and color. Consumables for household adhesive devices are produced with a thickness of 7-11 mm, and for professional devices - with a diameter of up to 45 mm. The length of the rod is not strictly set, it varies in the range of 4-20 cm, but the longer the reserve, the longer it can be used. Features of stickers by color:

- Transparent - universal, any material (plastic, fabric, metal, furniture).

- Multi-colored (blue, pink, green) - decorative sets, mask seams, are widely used in needlework and creativity.

- Black stickers are used for sealing; rods are suitable for carpets and flooring.

- Yellow rods are designed for paper products, cardboard and finishing materials.

- Glitter options are used in needlework, and white stickers are relevant for ceramics and tiles.

If the specifics of work require the use of black and transparent stickers, it is worthwhile to purchase two guns for each set of rods. We must not forget that the reserves are different in temperature and melt rate - 105-150 ° C. It is necessary to choose rods with glue, depending on the specific task and the features of the materials glued with thermoplastic hot-melt adhesive.

How to work with glue sticks without a gun

There are situations when you need to urgently fix / glue some fragments, and the gun broke. In this case, craftsmen and needlewomen use the following life hacks:

- A fragment of the rod is inserted into the body of the ballpoint pen and is held above the candle for melting. The glue must be constantly heated.

- A drop of hot glue is applied to the match near the sulfur head. If the gun overheats, you can light a match and use glue.

- A small fragment of the sticker is used instead of the eraser by gluing a small piece of the core onto the pencil.

But nevertheless it is more convenient to use glue stickers with the help of a thermogun. In order for the device to last longer, try not to allow overheating, which can lead to wear of rubber in the coupling, violation of the insulation of wires, unhindered leakage of glue.

How to change the color of the rod

Sometimes in the process of creativity, the needlewoman needs to use different stickers of different colors. In order not to break the gun, it is forbidden to pull out the glue from the coupling with pliers or other tools. The excess part of the sticker must be squeezed out through the nozzle by pulling the trigger. But before that, a new reserve of glue of the desired color is loaded into the gun. The spare rod will push through the rest of the sticker.

Masters recommend: If you often use a gun, a large number of short fragments of rods accumulate. The same color residues are glued together and get a new long sticker that can be used in work.

Problems and their solution

Glue guns even of professional type cannot be attributed to products with a long service life. If the model is used one-time to solve a specific household problem (for example, glue a carpet or fallen tile), the thermal device will last a long time. When the gun is often used to create works of authorship, the mechanism wears out, and the following problems may arise why the glue gun does not stick:

- The trigger is not pulled - the feed unit of the rods is broken or the pusher is stuck in a soft glue and cannot push the sticker. The gun is allowed to cool for several minutes and again try to pull the trigger.

- Glue flows out uncontrollably - high temperature is not suitable for a particular sticker, the core is inserted very tightly or its diameter does not match the parameters of the coupling. Need to fix the flaws.

- The glue does not flow from a well-heated gun - the nozzle clogged. The device is turned off, allowed to cool, remove the tip and thoroughly clean it.

- It is impossible to apply the adhesive pointwise, the substance reaches for the nozzle with a viscous stream - low quality rods. It is necessary for some time to put the stickers in the refrigerator, repeat the work.

Household pistols are designed for continuous use within half an hour. Then the device is turned off and paused. If you do not adhere to such a recommendation, the tool will quickly fail. You can not heat the device without rods, put a hot thermal gun on its side - it has a stand or a folding bar. In order to get reliable joints as a result of work, you need to act quickly and tightly to press the glued surfaces. The remaining glue is easily removed with a sharp knife.

The glue gun is a compact device that is very useful in everyday life and for creativity. Tools and supplies are inexpensive, a thermal device does not spend a lot of electricity. It can be used to connect homogeneous and heterogeneous products and materials. When working, you should follow basic safety measures and prevent glue from getting on the skin. Using a gun, you can create unique author's works or use the device for domestic purposes.

Design

A device for working with hot glue is called a “hot gun” or “hot glue gun”. The device owes its name to its appearance, because in appearance it looks like a children's pistol. The body of the product of all models is made of refractory plastic. This lightens the weight of the device and simplifies the work with it. The hot glue gun is designed to glue various materials by using a special type of glue in the form of cartridges. More often, the device is powered by electricity: for operation, it is enough to plug it into a 220 W power outlet.

However, today there are other varieties that function through batteries or gas. Mobility adds to their advantages in work, but the lack of a fixed connection also has disadvantages. This is due to quick discharge, as well as insufficient heating of the glue.

Key structural elements are:

- case

- viewing window

- nozzle,

- nozzle,

- stand,

- trigger trigger

- Temperature regulator,

- adhesive dispenser

- power button.

Inside the case there is a special chamber for glue. In addition, fuses and heating elements are internal components of the device. The viewing window allows you to see the remaining amount of glue. The usual nozzle diameter is 3 mm for models with 11 mm rods and 1.5 mm for versions with a rod diameter of 7 mm. Professional models may have removable nozzles to change the size of the nozzle.

The heating element melts the glue sticks, and the glue is pressurized to the trigger from the nozzle to the outside. To ensure the safety of the user, the nozzle has a silicone casing.

Features

Despite the fact that the gun has a single purpose, it has 2 varieties. The device can be domestic or professional. The second products are automatic. They are used mainly on conveyors. In fact, these are low-power and high-power electrical appliances. Household devices differ in the mechanical supply of glue and may be different depending on the criteria presented to them.

For example, they differ in cartridge diameter. In stores you can buy devices designed for rods 7 and 11 mm. Less often on the shelves there are options for thermoguns for adhesive rods with a diameter of 8 and 12 mm. Usually, for domestic use, they try to choose a product with a cartridge diameter of 7 mm.

Analogs with a large diameter are characterized by a higher feed rate of glue, therefore they are convenient for work requiring a large area of gluing.

However, nozzle size is of great importance for needlework. The smaller the outlet diameter, the more accurately the molten adhesive mass is fed. For needlewomen, this factor is one of the most important when buying.

Instructions for use step by step

Before connecting the device to the network, you need to prepare a workplace. It is necessary to cover the work surface in advance, preventing the ingress of glue on it. You can use a silicone mat or ordinary cardboard for this. It is important to collect loose hair, to protect the workplace from children and pets. In addition, it is necessary to provide ventilation in the room where it is planned to work with hot glue.

When all the preparations have been completed and the workplace is covered, take the gun and put it on the existing stand so that the nozzle nose looks down. It is important that at the location of the nozzle the working surface must be covered from the glue, because when heated, some part of the glue (about 1 cm) will come out and can ruin it. After the hot glue gun is turned on and the power button is pressed, if there is one (the indicator lights up). Take the adhesive cartridge and insert it into the hole located at the end of the case.

The glue is gently pushed forward until it starts to rest. No foreign objects other than glue should not be placed in the hole. In addition, to use for a specific diameter, only appropriate diameter glue sticks need to be used. It is worthwhile to know that molten and subsequently hardened glue should not be put back into the hole and reused.

After the glue is placed in the hole, you need to wait for the device to heat up. On average, it takes 5-7 minutes from the moment of inclusion to ensure that the composition melts, provided that the glue is already inside the device.Do not press the trigger at this time, checking how well the glue has warmed up and melted. This may cause damage to the glue gun itself.

If the device has an adjustment of the heating temperature, set the operating temperature within 105-200 degrees. With a lower rate, the glue will melt for a long time, with a larger one, it will begin to form threads. If the model is equipped with an adjustment of the trigger, you need to tighten the screw to set the approximate amount of glue at the exit.

When the glue is heated, it is applied to one of the surfaces to be glued. Do this by gradual pressure on the trigger, dosing the molten mass. Its amount will depend on the force of pulling the trigger. After the composition is applied to one of the surfaces, the gun is put in its original position and two materials are connected.

When the rod comes to an end, insert another cartridge. This is necessary so that he gets into the gripping mechanism and shoves the ending piece of glue. At the end of the operation, the device is turned off from the network and wait until it cools down. You can then remove it until next use.

Using a thermogun is not difficult: usually when working, there are no difficulties, whether it be needlework or the use of the device in construction.

Safety precautions

When working with a hot glue gun, safety precautions must be observed. It is important to protect not only the workplace, but also clothing, since glue can also be got on it. If you need to melt the glue or make any needlework with it, this is done immediately. When the device is not needed, it is immediately turned off, even if a break is planned for about 15-20 minutes.

It is important to check the integrity of the chassis and network cable every time before work. If any malfunction is detected, as well as the smell of smoke, immediately turn off the power to the device and stop using it. This tool should not be left unattended. In addition, its incorrect position can lead to the fact that the heated glue gets into the electrical circuit, which will cause damage to the device.

Do not overheat the hot glue gun, because of this the glue inside it will boil. In addition, you can not touch the molten composition, since it will leave burns on the skin in places of contact. You need to work with the device extremely carefully and accurately. No contact with metal parts. It is not allowed to remove the rod from the gun when it is heated.

The storage device can only be removed when it has completely cooled down. In order to avoid a short circuit, you cannot buy cheap products without the proper documentation, as they can cause a fire. In case of a burn, the skin is treated with a special ointment, the work is stopped.

What else do you need to know?

Many do not know that the glue used for the thermogun is different. The adhesion strength depends on this. They differ in the degree of transparency, they are colored and even black. The composition of the glue stick determines the type of material used. In other words, one type of glue, even when fully heated, is not universal.

Transparent adhesive is considered more universal, since it is suitable for bonding various materials.including paper, glass, fabric, plastic, PVC, metal, cable, electrical equipment. The white analogue is used in work with tiles, ceramics and plastic. Colored rods perfectly mask the seams and create a uniform tone. Black is suitable for leather and carpets, while yellow is used for cardboard and wood.

In addition, the rods differ in melting point. They are standard (105 degrees) and high temperature (150 degrees).

Reserves must be selected correctly, because if the rod needs high temperature, and the gun is not designed for this, good adhesion and proper melting will not work.

Reviews

The thermogun is sold in specialized stores and is used for various purposes, as evidenced by customer reviews left on the World Wide Web forums. A lot of comments are devoted to household devices that users like for convenience and ease of use. With their help, you can create unique creative compositions, decorative bouquets of toys, decorate sweets, make flower hairpins and a variety of jewelry. At the same time, needlewomen note that thermal guns allow you to work accurately, without overspending glue.

See how to make flowers with a glue gun.

Not heated

Most likely, the ceramic heating element has failed. Separately, unfortunately, this item is not for sale. It happens that the heat gun warms, but not more than +110 degrees. Here, craftsmen share their advice: we buy and disassemble the "raptor", we get a carbon plate similar to that of an instrument, cast in ceramics and make a replacement. True, this solution is short-lived, as well as replacement requires accuracy and qualification - it is better to buy a new glue gun.

The heating plate may also deteriorate. Masters recommend in this case, directly on the nozzle, wrap a 5 W ceramic resistor with a resistance of 3.9 K.

It happens that there is no heating due to broken wires connected to the heat chamber. It’s enough to solder them to make it work.

Observe safety precautions

Glue guns, for the most part, relate to power tools, with rare exceptions - gas models, which are not often found on sale. Therefore, it is not recommended to use it for work in a damp room, where the floor covering acts as a conductor and there is a danger of electric shock.

Almost the entire external part of the tool is made of plastic which does not heat up to the temperature at which you can get a burn. But the nozzle through which the molten glue is supplied is made of metal and it is in contact with the heating element. Therefore, in the course of work, you should avoid touching the nozzle of the gun to avoid burns, as it heats up to high temperature.

It will not be amiss to make a small stand. Its construction is not complicated and it can be done using the very glue gun from wooden scraps or cardboard.

When working with the glue gun, adhere to the following safety precautions:

- Before connecting the tool to the network, make sure that its wire and body are intact, for this it is enough to make a visual inspection,

- remove glue residue from the nozzle after each use before cooling it with a thick cloth or other similar material,

- do not allow children to be near, as hot glue heats up to high temperatures and the child may accidentally burn himself,

- place foil or other material under the nozzle of the switched-on tool that will collect the flowing adhesive mass,

- do not touch the metal parts of the gun during operation,

- loose clothing is not recommended. Preference should be given to strong and dense fabrics, which, in which case, will protect against burns,

- long hair should be removed, jewelry removed,

- do not touch the glue just applied with your bare hands, let it cool,

- it is advisable to wear heat-resistant gloves on your hands.

Polymer glue does not emit toxins harmful to the human body. But he poses another danger - in a warmed state, he can easily leave a burn with careless handling. Make sure that the tool, or rather, its nozzle, is always facing the opposite direction from you.

Conclusion

The hot-melt adhesive method is gaining more and more fans. The thermogun is a universal, easy-to-use tool that provides almost instant grip of various materials and surfaces. At the same time, the adhesive used does not emit harmful toxins, and the adhesive joint is reliable and durable. This device is used both for solving everyday problems, and for creative work, needlework.

What is a glue gun and where is it used?

The main advantage of this device is its simplicity and ease of use, and consumables cost a penny. And the device itself is not expensive, but it opens up a ton of possibilities. The thermogun is in the arsenal of builders, it helps fix engineering communications, seals, glues, fills seams. It is used by needlewomen, florists, designers, giving the opportunity to glue various accessories, to make all kinds of designs.

Radio amateurs actively use glue guns in the repair of microcircuits, wiring. Even artists saw decorative value in the polyurethane melt, creating designs from the adhesive mass. In household use, this thing is not replaceable, with the help of such a gun you can even restore broken dishes.

The glue gun connects various parts almost immediately, since the polymer, heated to a certain temperature, hardens in just a few minutes, the gluing is strong and does not make it wait for setting, unlike other types of glue. A hot gun is used in working with wood, plastic, leather, glass, metal, paper, ceramics, fabric, PVC, rubber, foam.

It is not recommended to use it with concrete or plaster, although this is a debatable issue, tests show that a metal hook glued to the wall can withstand a relatively large weight. It is rarely used in working with polyethylene, since at high temperature it melts and deforms. Polymer glue is not used in places with a temperature equal to the melting point of the glue itself. And most importantly, if you need to remove glue from almost all surfaces, this can be easily done.

The hardened polymer is elastic and moisture resistant. Polymer glue is harmless.

It is necessary to work with such a tool carefully, adhering to safety rules, since burns are possible, the melting temperature of the glue reaches 200 degrees.

The principle of operation of a hot glue gun

Thermogun is a hand tool, very similar to the type of weapon. It also needs to be charged, not with live ammunition, but with cylindrical rods of polyurethane adhesive of various diameters. The gun itself is made of heat-resistant plastic, which makes it easy. Powered by a 200 W outlet, some models are equipped with a built-in battery. On the back of the device there is a hole in which the glue stick is inserted, the diameter of the tube depends on the model.

Spare glue enters the sleeve of the pusher mechanism, falling into a special pipe - a rubber receiver, and from it the edge of the rod abuts against the heating chamber, in which the polyurethane melts, turning into an adhesive mass. It takes no more than 5 minutes to heat up the instrument after turning it on. On the handle of the unit, like a real gun, there is a trigger. With its help, the piston starts, creating pressure in the heating chamber, which allows the liquid glue to be pushed out through the nozzle to the surface of the material to be glued.

The performance of the tool directly depends on the heat chamber, which is located in the barrel of the thermal gun. The size of the chamber and the power of the heating element affects the amount of molten adhesive mass and the polymer melting rate.

When choosing a tool, you must definitely pay attention to the feed mechanism, as this is a moody design and often breaks.

The nozzle of a hot gun gives the glue a shape and doses the flow of molten mass. It is made of metal. Some brands produce tools with different nozzles that differ in length and shape.

It is important not to forget after each use of the unit to clear the nozzle of glue.

The latest models of glue guns are also equipped with a backlight, which is important when working with it in a room with poor visibility or even in the dark.

There is a viewing window on the glue gun body, this is an important option for monitoring the remainder of the rod. Almost all devices are equipped with a hinged stand, for supporting the tool with the nozzle down, since they do not recommend putting the gun on one side, the case can overheat.

The power of a thermogun is an indicator of the speed of “thawing” of the glue stick. The higher the power, the faster the glue melts. Professional hot pistols from three hundred watts, and amateur up to 150 watts. Some devices are equipped with a power regulator. The heating indicator - a light on the gun body, will show when it is possible to start work, and the glue melts to the desired temperature. The melt temperature of the glue is also of great importance, since some materials do not withstand high temperatures.

There are tools for a certain material, but it is more profitable to purchase a unit with a controlled temperature. Any rod melts at 105 degrees, and a temperature higher simply accelerates this process.

Spare rods for a hot gun vary in diameter, color and operating temperature. Stickers can be of different lengths (from 4 to 20 cm). The diameter of the rod is selected according to the configuration of your gun.

Colored rods are designed to mask seams or to decorate. Universal adhesive is transparent, black is intended for sealing, yellow is used for glass. Even spangled rods have appeared on the market, which opens up more opportunities for decorators.

Preparing to work with a thermal gun

The principle of operation of hot glue guns is the same and you need to know step by step how to use it. This is an electric tool, so safety is mandatory. Before each use, you need to inspect the device, there should be no damage to the gun body. Any not noticed even the smallest crack can lead to problems. Next, inspect the nozzle, it should not be clogged.

The rod is inserted into the connector until it stops, a new sticker is added only after the first one has been used up.

Straighten the cord before plugging it into a power outlet. Often the length of the cord does not allow free use of the tool, in which case you need to use an extension cord. On the body of the gun there is a switch that allows you to adjust the temperature of the adhesive. The heat chamber does not melt the glue after a while, as it needs to be warmed up. The indicator shows the start of work with the device.

Hot Gun Algorithm

When the inspection is over, proceed to work with the device. If you use the tool correctly, then an excellent result will be guaranteed.

The polymer heats up over time, so do not rush to pull the trigger immediately after turning it on. While the appliance is warming up, the material is prepared for work. The surface of the material must be clean and degreased. The desired polymer volume is adjusted by pulling the trigger. Squeeze out only the amount of polymer that is needed.

The polymer in the molten state holds the temperature for a few more seconds. During this time, it must be applied to the material and pressed against each other. Melt slowly. A large amount of polymer will require more time for bonding.

During a break in work, the device must be placed on a stand so that hot glue does not flow into the gun.

Do not exceed the use time of the included toolspecified in the instructions to it. A professional thermal gun can be used for 2 hours, guns for creativity need to be turned off after 20 minutes.During a break in work, a thin cobweb can form, which is not difficult to remove in a solid state. After finishing work, you should wipe the tip from the remaining glue.

Advantages and disadvantages of a thermal gun

The benefits are numerous. Such a hot gun provides instant bonding. The bonding strength is high, it glues the same materials well together, and combinations of materials with each other. The appearance of the glued surface has an excellent appearance. There is a large palette of glue sticks, you can choose a color for any surface. This tool is not replaceable during fastening, where you need to do without mechanical stress. It is believed that it is environmentally friendly and absolutely safe.

The shortcomings of the thermal gun are few. It does not adhere well to polyurethane with concrete, plaster and cement. And you can not use this device in a place where the part glued with such glue will undergo further heating. For needlework, this unit is ideal. With it, you can do unique things.

For more information on adhesive cartridges, see the next video.

Function and tool design

In appearance, the device is very similar to a gun, which played a role in the choice of name. For work the glue gun is refueled special polyurethane rods that melt, turning into a fluid consistency. The latter quickly freezes, fixing together different materials.

The rods are installed in the gun from the back. Today, there are models that can work with rods 7-11 mm in diameter. Glue sticks are placed in a special receiver, where the tip of the material is in the heating module.

As already noted, when heated, the rod melts, becoming a viscous state, at which time the material receives penetrating and adhesive properties, but not for long - for about 5 minutes! When you pull the trigger, the adhesive mass pours out of the nozzle, falling on the work surface.

For a long time, the design of the hot glue gun has not changed, offering all the same 4 main elements:

- Nozzlecalled nozzle or nozzle. Using it, you can adjust the dosage of the adhesive composition extruded to the surface. The shutoff valve located inside the nozzle prevents accidental leakage of the solution. The nozzle itself is made of a metal alloy, from the outside it is covered with a heat-insulating material. For preventive purposes, after operation, the nozzle should be cleaned well,

- The next equally important element in the design of the glue gun is coupling. It is placed directly in front of the heating chamber and has the form of a tubular receiver. The coupling provides tightness, preventing the molten composition from penetrating into the structure. It is worth noting that a breakdown of the coupling often renders the tool unusable,

- Feed unit made as ring pusher that starts to move when you pull the trigger. It is performed mechanically, and therefore its design can hardly be called a reliable part of the mechanism, since when pressed hard, trigger breakage is not excluded. At the same time, for each type of hot-melt glue gun, they must use their own rods - with the right diameter! In extreme cases, working with the tool will be difficult, in the worst case, the gun will break,

- Heating module placed inside the barrel, performed in the form of a metal container. The heating unit is located at the bottom of the camera. In models of a higher price category, there may be several heating elements at once. The performance of the glue gun largely depends on the volume of the chamber and the power of the heating elements.

The most reliable element in the design of the tool is considered to be the heating unit, since it is able to work properly throughout the entire period of operation.

As for the case, it is made of durable and solid polymers, which not only tolerate the action of high temperatures well, but also do not allow this heat to be transmitted through itself to the hand of the master. Some products in their design provide for special windows through which you can observe the remainder of the rod.

To better grip the handle, its surface is equipped with an anti-slip insert. Often manufacturers complement the package special stand with which the work with the tool becomes much more convenient.

Hot melt guns have been widely used both in construction and in everyday life, making it possible to glue various materials in the simplest, fastest and most qualitative way.

Varieties

Today in the store you can find several types of hot-melt gun, which differ in some design features. In models with a carousel trigger, glue is squeezed out when the trigger is rotated along the axis. Other versions offer triggers in the form of sliders, when pressed, the adhesive enters the camera parallel to the barrel.

There are versions on the market that allow you to change the heating temperature. Such devices allow working with rods with different melting points.

Small models are equipped with a long nozzle. Such devices in most cases are purchased for children, because in them it does not take a lot of force to pull the trigger, and the power of the device is minimal.

Hot glue gun - a great tool for repair! In addition, often it finds its application in construction. A wide variety of models on the market makes it possible without particular difficulties to choose the version that most closely matches the requirements for work, and a considerable assortment of power and type of design allows you to use the device when performing both domestic and production tasks.

Such a device as a hot glue gun came to the power tool market only a few years ago, so this product can not be found in every home. However, on the other hand, in every household there is a problem that can be easily solved by using a glue gun, since repairing certain things with gluing is a fairly common occurrence.

The glue gun owes its “combat” name to its resemblance to the weapon of the same name. Indeed, the body of the product is very similar to a combat pistol - a similar shape, the presence of a trigger, a barrel. Yes, and with cartridges you can draw an analogy - the thermal gun is “charged” with glue sticks.

Tool class

Like other positions of power tools, various models of thermoguns are classified into professional and household models. When choosing a product for domestic use, do not pay attention to professional and expensive models, because in this case we are talking about tools for any production.

Enterprises operate continuously with automatic and constant supply of glue sticks, or in positions with an increased resource and high cost. For amateur use, a household class tool is quite suitable, the cost of which usually does not exceed 1000 rubles.

Consumables

The main difference between the glue sticks is the size of their diameter. It can have two indicators - 7 and 11mm.

Before use, it is necessary to find out what diameter the rods are supported by this model of glue gun.

If you intend to use the tool from case to case, a pistol with a seven-millimeter rod is enough.

If we are talking about constant repair work with a relatively large consumption of glue, it would be optimal to purchase a model with an eleven-millimeter core.

For example, the model of the glue gun PK 11/100 of the Stavr trademark. The number 11 in the article indicates the value of the diameter of the consumable element.

The melting temperature

Intuitively, one can also guess the layman - the higher the heating temperature, the greater the productivity of the tool.

For a household-class tool, the temperature ranges from 105-200 degrees. This run-up is due to the fact that some materials are sensitive to high temperature (paper, cardboard, rubber) and when working with these things the minimum melting point is set, that is 105 degrees.

However, not all models of thermoguns have the ability to adjust the temperature, and therefore the value of this parameter is constant (for example, only 105 or only 200 degrees).

Positions with the ability to adjust are in the line of thermal guns of the Dremel brand.

If you have not acquired such a useful tool as a glue gun, you should seriously think about buying. This is a multi-purpose electrical appliance designed for melting polyurethane rods. The molten material adheres well to various materials, providing a reliable and durable joint, stable in water and various liquids.

Due to the properties of polyurethane, the molten mass can be used for gluing plastic, metal, wood or to create various decorative products, design, modeling. Such tools are widely used by builders, designers, florists, and a thermogun is also suitable for children's creativity.

Use of the device in construction

Using a thermal gun, you can perform various construction and repair work. For such purposes, powerful models with a large diameter of the glue stick are best suited. They can quickly distribute a large amount of adhesive on a vertical or horizontal surface.

What construction and repair work can be done with a glue gun?

- Fill cavities, cracks and even holes of small or medium diameter.

- Fix wires or utilities.

- Connect the glass parts or glue the glass elements to the base.

- The polyurethane compound glues wood and plastic skirting boards, lightweight polymer constructions that will not be heavily loaded, plastic panels, hooks, and decorative ornaments.

A good polyurethane composition adheres to almost all surfaces, but you should know when working with what materials its properties are useless:

- concrete,

- brick,

- silicone

- drywall

- Styrofoam,

- low density polyethylene.

The universal polymer composition is very convenient to heat up and make various piece products from it, to do decorative work or to draw with a molten mass of different colors. Often the glue gun is used in modeling, manufacturing frames and other structures.

If the device is purchased for needlework, special attention should be paid to its configuration - in some models there are a number of different nozzles with different nozzle diameters or elongated feed spouts, which is convenient when working in blind spots or indentations.